Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How do injection molding machines work?

Injection molding is a high-volume manufacturing process used to produce precise plastic parts by injecting molten material into a custom mold. It's widely applied in industries like automotive, electronics, medical devices, and consumer goods to create everything from small components to large panels. The process relies on specialized machines that apply immense pressure (often thousands of PSI) to ensure the material fills complex shapes accurately before cooling and solidifying.

Main Components of an Injection Molding Machine

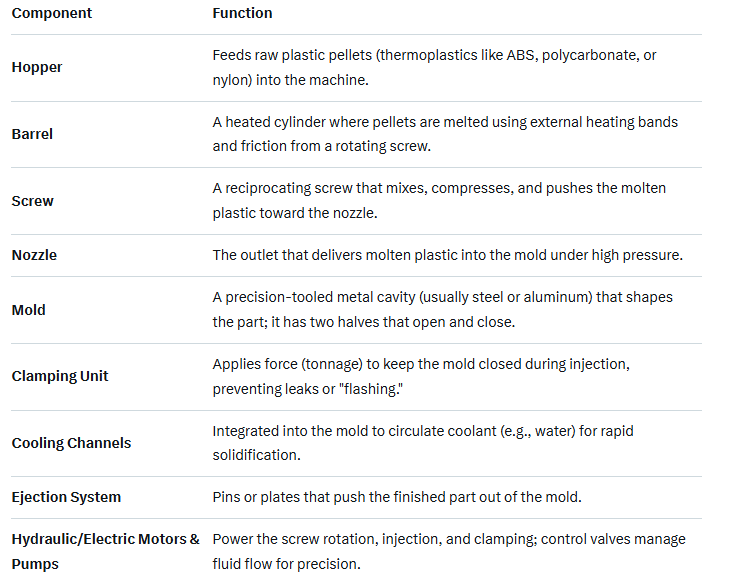

An injection molding machine consists of two primary units: the injection unit (which melts and injects the plastic) and the clamping unit (which holds the mold). Key components include:

How Injection Molding Machines Work: Step-by-Step Process

The process is cyclical and automated, typically taking seconds to minutes per cycle for high efficiency. Here's how it unfolds:

1.Material Feeding: Plastic pellets are loaded into the hopper and gravity-fed into the barrel. The machine is set with parameters like temperature (200–300°C depending on material), pressure, and injection speed.

2.Melting and Plasticizing: Inside the heated barrel, the screw rotates to shear and melt the pellets into a viscous liquid. The screw also acts like a piston, building pressure by pushing the melt forward.

3.Injection: The screw (or plunger in older designs) rapidly advances, forcing molten plastic through the nozzle into the closed mold cavity at high speed and pressure (up to 20,000 PSI). This fills the mold in milliseconds, ensuring no voids form in intricate details.

4.Packing and Holding: Additional pressure is applied briefly to compensate for material shrinkage as it cools, maintaining dimensional accuracy.

5.Cooling: Coolant flows through the mold's channels, solidifying the plastic in 10–60 seconds. The mold's design (e.g., draft angles of 1–2° on walls) aids easy ejection and prevents warping.

6.Mold Opening and Ejection: The clamping unit releases, the mold halves separate, and ejector pins push out the part. Runners (excess plastic channels) are trimmed off.

7.Repeat: The mold closes, and the cycle restarts. Machines can run 24/7, producing thousands of identical parts per hour.

Key Considerations and Advantages

Factors like material choice (e.g., polycarbonate for heat-resistant parts) and mold design heavily influence success. While upfront tooling costs are high ($1,000–$100,000+), the process excels for volumes over 10,000 units due to low per-part costs. Common challenges include defects like sink marks or flash, mitigated by precise control systems.This method, pioneered in the 1870s, has evolved with automation and 3D-printed prototypes for faster iterations.