Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How long does injection molding take?

The time required for injection molding primarily refers to the cycle time, which is the duration to complete one full production cycle for a single part (or set of parts from a multi-cavity mold). This includes injecting the molten material, cooling it, and ejecting the part. Cycle times can vary widely based on factors like part geometry (e.g., wall thickness), material type (e.g., polypropylene vs. ABS), mold design, machine capabilities, and production volume.

Typical Cycle Time Range

General range: Most injection molding cycles last 10 seconds to 2 minutes per part.

Shorter cycles (e.g., 8–25 seconds) are common for simple, thin-walled parts like bottle caps, while complex or thicker parts can take longer.

Breakdown of Cycle Time Components

A full cycle typically consists of these phases, with approximate proportions:

Injection/fill time (1–5% of total): 1–5 seconds; time to inject molten plastic into the mold.

Packing/holding time (5–10% of total): 2–10 seconds; applies pressure to compensate for shrinkage.

Cooling time (80–90% of total): The longest phase, often 10–60+ seconds; depends heavily on wall thickness (thicker walls = longer cooling) and material thermal properties.

Mold open/eject/dry cycle time (5–10% of total): 2–10 seconds; includes opening the mold, ejecting the part, and closing it again.

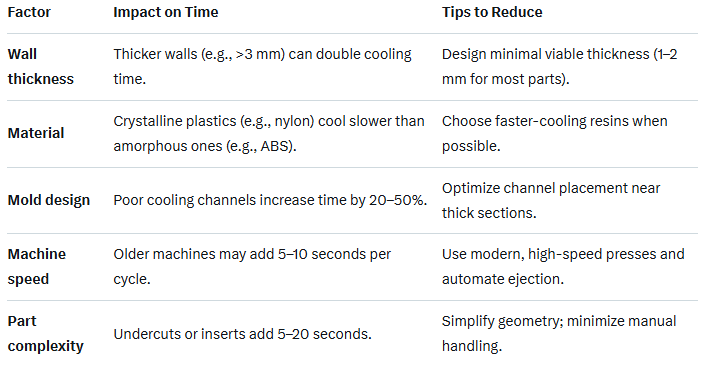

Factors Influencing Cycle Time:

For high-volume production (e.g., millions of parts), even a 1–2 second reduction per cycle can save significant time and cost. Software like Moldflow can simulate precise times, but real-world testing is essential. If you provide details like part specs or material, I can help refine an estimate.