Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to avoid air bubbles in injection molding?

Air bubbles (also known as gas traps, voids, or blisters) in injection molded parts are common defects that can compromise structural integrity, aesthetics, and functionality. They often result from trapped air, moisture vaporization, material degradation, or uneven cooling/shrinkage. Distinguishing between true gas bubbles (trapped air/gas) and vacuum voids (shrinkage-related) is key—warm the defect area with a heat gun; if it collapses into a sink, it's a void; if it expands, it's gas.

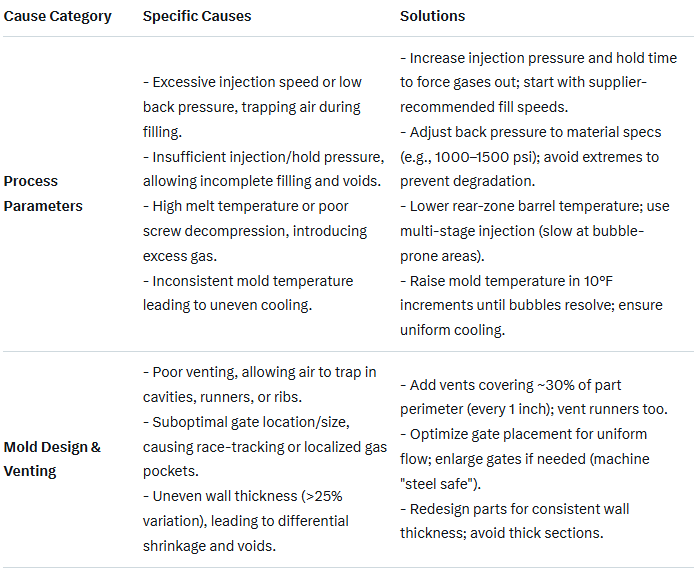

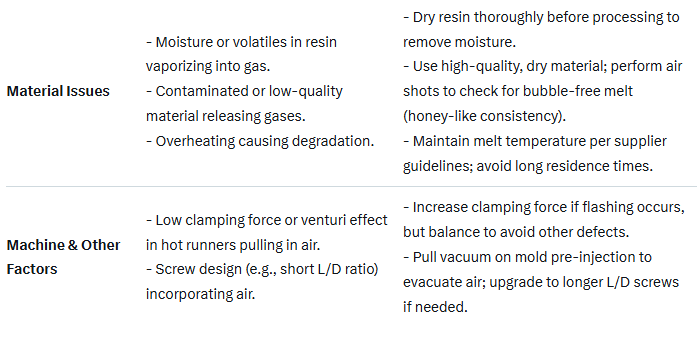

To avoid them, focus on optimizing process parameters, mold design, and material preparation. Below is a structured overview of common causes and targeted solutions, drawn from industry best practices.

Additional Tips for Prevention

1.Short Shot Testing: Run partial fills (10–95% volume) at constant velocity to visualize flow patterns and pinpoint bubble origins.

Quality Control: Inspect parts regularly for defects; monitor parameters in real-time.

2.Holistic Approach: Start adjustments with short shots to minimize waste. If issues persist, consult material suppliers or use mold coatings for better release and venting.

3.When to Seek Expertise: For complex parts (e.g., transparent ones), involve tuning specialists early, as bubbles can mimic voids.