Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to avoid jetting in injection molding?

Jetting is a common defect in injection molding where the molten plastic enters the mold cavity too rapidly or turbulently, often through a restrictive gate or nozzle, resulting in a "worm-like" or serpentine swirl pattern on the part's surface. This occurs due to poor flow control, leading to uneven cooling and weak structural integrity. It is typically caused by factors like high injection speed, low material temperature, improper gate placement, or small runner/nozzle sizes.

Preventing jetting involves adjustments to mold design, process parameters, and material selection. Below is a comprehensive guide to avoidance strategies, grouped by category for clarity.

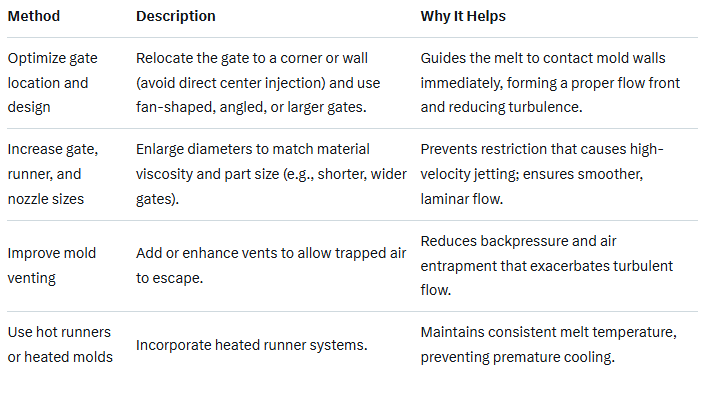

Mold Design Adjustments

These changes focus on improving flow dynamics before and during injection:

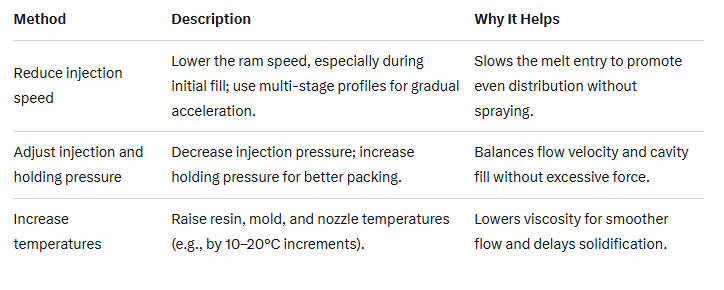

Process Parameter Adjustments

Fine-tune machine settings to control flow speed and pressure:

Material Selection and Other Tips

Choose low-viscosity resins: Opt for high-flow materials (e.g., switch from HDPE to polypropylene if compatible) to minimize resistance.

Test iteratively: Simulate or prototype with software/tools to predict flow; monitor for jetting during trials and adjust one variable at a time.

Quality assurance: Partner with experienced mold makers for design validation to catch issues early.