Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to calculate cavity pressure in injection molding?

Cavity pressure refers to the actual pressure exerted by molten plastic inside the mold cavity during the injection molding process. It is a critical parameter that influences part quality, such as dimensional accuracy, surface finish, and defect prevention . Unlike injection pressure, cavity pressure is lower due to viscous flow losses through the sprue, runners, and gates—often 40–60% of the injection pressure.

There is no single universal "plug-and-play" formula for cavity pressure because it depends on factors like material viscosity, mold geometry, injection speed, temperature, and gate design. Instead, it is typically estimated for initial design, measured directly, or simulated.

1. Estimation for Design and Clamping Force Calculation

For preliminary calculations (e.g., sizing the machine's clamping force), cavity pressure is approximated as a percentage of the machine's peak injection pressure or a material-specific fixed value.

2. Direct Measurement

For precise control, embed pressure sensors (transducers) in the mold cavity walls, typically near the gate or end-of-fill location.

3. Simulation-Based PredictionUse CAE software for detailed modeling without physical trials.

Key Considerations

1.Units: Use consistent units

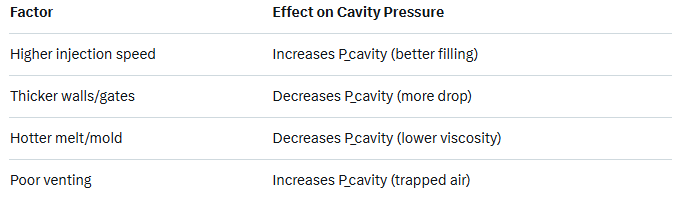

2.Influencing Factors:

3.Common Errors: Overestimating P_cavity leads to oversized machines; underestimating causes flash or incomplete fills.

4.Best Practice: Start with estimation, refine with measurement/simulation, and monitor in production.