Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to calculate clamping tonnage for injection molding?

Clamping tonnage (also called clamping force) is the amount of force required to keep the mold halves closed during the injection process. This prevents the molten plastic from forcing the mold open, which could cause defects like flash (excess plastic at the parting line), incomplete fills, or damage to the mold or machine. It's typically measured in tons (1 ton = 2,000 lbs) and determines the size of the injection molding machine needed. Insufficient tonnage leads to part defects, while excessive tonnage can waste energy, increase wear, or cause machine strain.

Step-by-Step Guide to Calculate Clamping Tonnage

1.Determine the Projected Area of One Cavity

2.Account for Multiple Cavities, Runners, and Sprue

3.Select the Clamping Factor

4.Calculate the Tonnage

5.Refine with Additional Factors (Optional Adjustments)

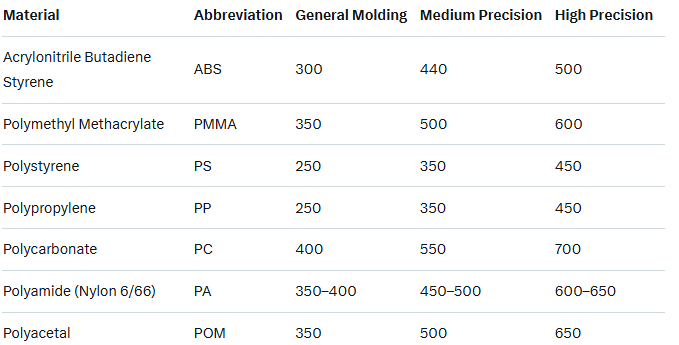

Typical Clamping Factors by Material:

Factors can vary by part geometry (e.g., thin walls need higher factors) and process (e.g., more gates lower the factor).

Factors Affecting Clamping Tonnage

1.Part Design: Longer flow paths or thin walls increase pressure needs. Thick sections require high pack/hold pressure to compensate for shrinkage.

2.Gating: More gates (e.g., 2 vs. 1) reduce pressure by 20–50%; sequential valve gating can cut tonnage significantly for large parts.

3.Material Properties: Viscosity (via MFI) and thermal shrinkage influence fill vs. pack pressure—pack often governs for defect-free parts.

4.Mold Orientation: Align the largest projected area perpendicular to clamping to minimize tonnage.

5.Machine Optimization: After calculation, test empirically: Start at 3.5–4 tons/in², reduce in 5-ton steps while monitoring shot weight and dimensions until flash appears, then add 5–10 tons.