Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to calculate cooling time in injection molding?

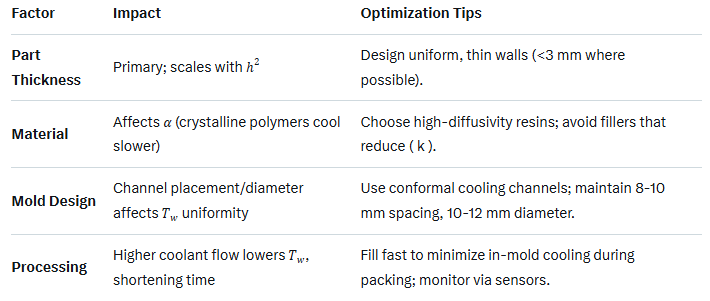

Cooling time is a critical phase in the injection molding process, typically accounting for 70-80% of the total cycle time. It refers to the duration required for the molten polymer to solidify sufficiently in the mold to maintain its shape upon ejection, preventing defects like warping or distortion. Accurate calculation helps optimize productivity, energy use, and part quality.The most widely used analytical method is based on the one-dimensional heat conduction model for a flat plate (assuming uniform cooling from both sides), derived from Fourier's law of heat conduction. This empirical formula estimates the time for the center of the part to reach the ejection temperature.

Step-by-Step Calculation

1.Gather material properties

2.Measure part geometry

3.Determine temperatures

4.Plug into the formula

Add safety factor: Increase by 10-20% to account for variations in material, machine performance, or non-ideal heat transfer.