Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to calculate injection molding tonnage?

Injection molding tonnage, also known as clamping force, refers to the amount of force (measured in tons) that an injection molding machine's clamp applies to keep the mold closed during the injection process. This prevents the molten plastic from forcing the mold open, which could cause defects like flashing (excess plastic at the parting line). Insufficient tonnage leads to incomplete fills or flashes, while excessive tonnage can damage the mold, increase cycle times, or cause issues like burns from trapped air. Accurate calculation ensures optimal machine selection, part quality, and cost efficiency.

Step-by-Step Guide to Calculating Tonnage

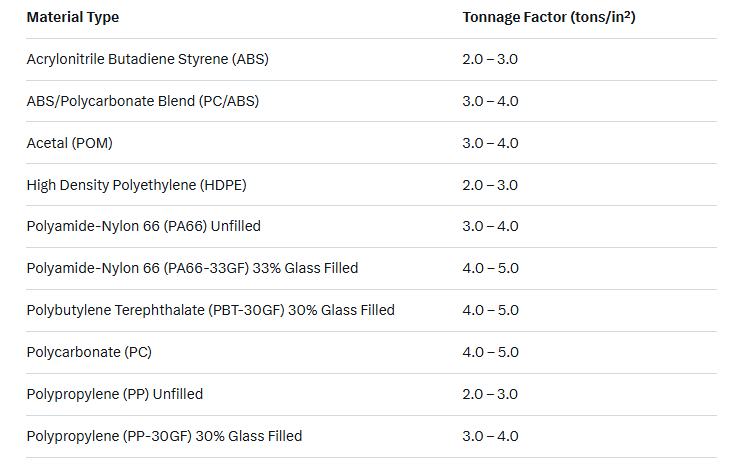

The calculation focuses on the projected area (the area at the mold's parting line where plastic exerts pressure to open the mold) multiplied by a tonnage factor (a material-specific value in tons per square inch, typically 2–8 tons/in²). Include a safety factor (e.g., 1.1–1.5) for variability. Here's how to do it:

1.Calculate the Projected Area of the Parts:

2.Calculate the Projected Area of the Runners:

3.Determine the Total Projected Area:

4.Select the Tonnage Factor:

5.Calculate the Required Tonnage:

Common Tonnage Factors by Material