Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Is injection molding cheap?

Injection molding is not inherently "cheap" in absolute terms—especially for low-volume or prototype production—but it becomes highly cost-effective for medium- to high-volume manufacturing (typically 1,000+ parts) due to its efficiency and low per-unit costs once the initial tooling is amortized. The overall affordability depends on factors like production volume, part complexity, material choice, and tooling quality. Below, I'll break it down.

Key Cost Components

Tooling (Mold) Costs: This is the biggest upfront expense, ranging from $10,000–$100,000 (or more for complex molds), as it requires precision machining of a durable steel or aluminum mold. Simple molds can be cheaper ($2,500–$5,000)

Per-Part Production Costs: Once tooled, each part costs $0.01–$0.50 to produce, influenced by material (e.g., plastics like ABS or nylon add $0.05–$0.20 per gram), cycle time (20–60 seconds per part), and labor/setup. Energy costs are minimal, at about $0.002 per small part.

Other Factors: Part complexity (e.g., undercuts or thin walls) increases costs by 20–50%. Secondary operations like assembly or finishing add 10–30%. High volumes spread fixed costs, dropping per-unit prices dramatically.

Comparison to Alternatives

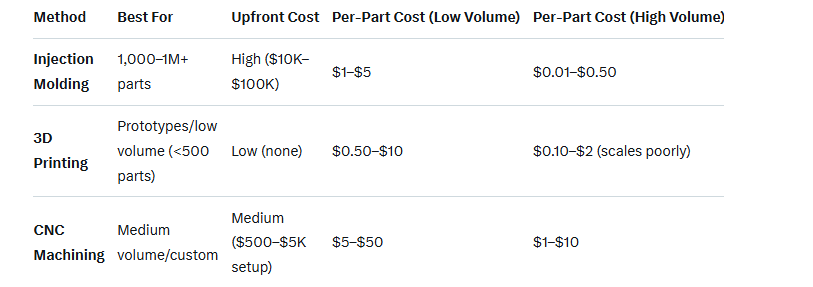

Injection molding shines in scalability but lags for small runs:

For example, at 100 parts, 3D printing might total $500–$1,000, while injection molding exceeds $10,000 due to tooling. But at 10,000 parts, injection drops to ~$0.20/unit vs. $2+/unit for 3D printing.

In summary, injection molding is a smart, "cheap" choice for mass production but a poor one for small batches.