Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Is injection molding expensive?

Injection molding can be expensive upfront due to the significant investment in tooling and setup, but it often becomes highly cost-effective for high-volume production runs. Here's a breakdown based on key factors:

Upfront Costs (Tooling and Setup)

Mold creation: The biggest expense is designing and manufacturing the mold itself, which can range from $100 for a simple 3D-printed low-volume mold to $100,000+ for a complex, multi-cavity steel mold used in mass production. Quotes for a single die can hit $40,000–$50,000, factoring in CNC machining, polishing, and design testing.

Overall project costs: Total injection molding expenses typically fall between $10,000 and $100,000, depending on part complexity, order size, and material choices.

Smaller prototypes might cost less (e.g., around $2,500 for basic efficiency gains), but scaling up drives prices higher.

Per-Unit Costs

Once the mold is made, production costs drop dramatically—often to pennies per part for large runs (e.g., 100,000+ units). This makes it cheaper than alternatives like CNC machining or 3D printing for mass production. The primary driver here is cycle time: simpler parts with shorter molding cycles reduce machine runtime and labor costs.

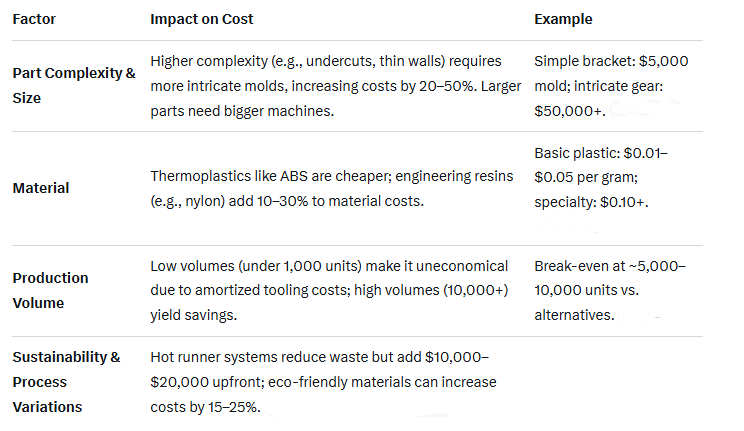

Factors Influencing Cost:

In summary, injection molding isn't inherently "expensive" if your project justifies the initial outlay—it's a strategic choice for efficiency in volume manufacturing.