Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Is injection molding stronger than 3d printing?

Yes, injection molding generally produces stronger parts than 3D printing, particularly in terms of tensile strength, impact resistance, and overall durability. This holds true for common materials like ABS plastic, though the exact difference can vary based on factors such as the specific 3D printing method (e.g., FDM vs. SLS), print orientation, infill density, and post-processing.

Key Reasons for the Strength Difference

Manufacturing Process: Injection molding forces molten material into a mold under high pressure and temperature, creating a dense, uniform, and isotropic structure (equal strength in all directions) with minimal defects. In contrast, 3D printing (especially FDM) builds parts layer by layer, leading to anisotropic properties—stronger within layers but weaker between them due to poorer interlayer bonding.

Material Density and Consistency: Injection molded parts achieve near-100% density, while 3D printed parts often have voids or gaps, reducing load-bearing capacity.

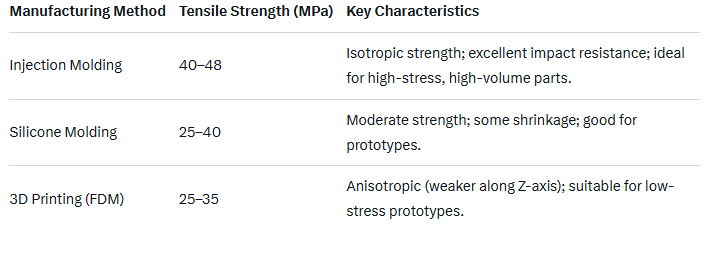

Quantitative Comparison (for ABS Parts)

Here's a summary of tensile strength data from a direct test comparison:

When 3D Printing Might Compete

Advanced 3D printing techniques like selective laser sintering (SLS) or multi-jet fusion (MJF) can narrow the gap by improving density and isotropy, sometimes achieving 80–90% of injection molded strength. However, for most applications requiring maximum strength and consistency, injection molding remains superior—especially at scale.