Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Is thermoforming cheaper than injection molding?

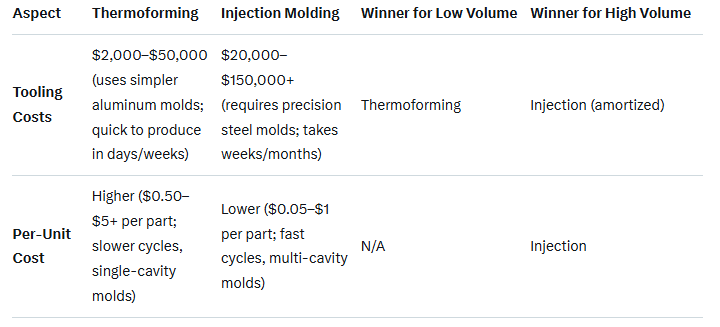

Thermoforming and injection molding are both popular plastic manufacturing processes, but whether thermoforming is cheaper than injection molding depends primarily on production volume, part size/complexity, and other factors like material and labor. In general:

Thermoforming is cheaper for low-volume production (e.g., under 3,000 parts) due to significantly lower upfront tooling costs and faster lead times.

Injection molding is cheaper for high-volume production (e.g., over 10,000–30,000 parts) because of lower per-unit costs once the initial investment is amortized.

Key Cost Comparison

Here's a breakdown based on typical industry data:

When to Choose Each

Opt for thermoforming if you're prototyping, producing large/thin parts (e.g., packaging trays, vehicle panels), or running short batches—savings can be 20–50% on upfront costs.

Opt for injection molding for mass production of precise, small parts (e.g., bottle caps, gears)—per-part costs drop dramatically at scale, often making it 2–5x cheaper overall for big runs.