Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What are the raw materials used in injection molding?

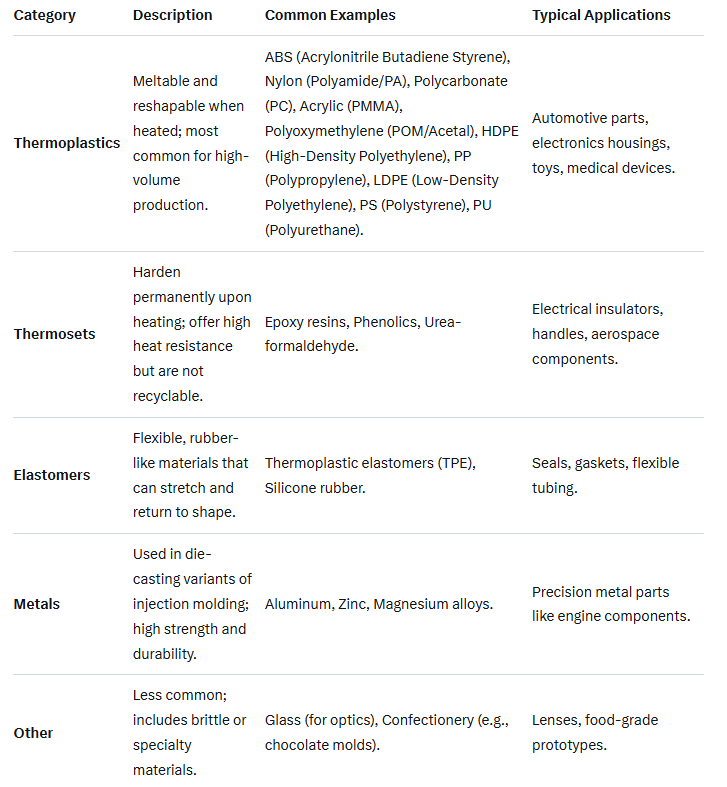

Injection molding is a versatile manufacturing process where raw materials are heated to a molten state, injected into a mold cavity, and cooled to form solid parts. The choice of material depends on factors like mechanical properties, cost, environmental resistance, and application (e.g., automotive, medical, consumer goods). While thermoplastics dominate due to their recyclability and ease of processing, other categories like thermosets, elastomers, metals, and even glass or confectionery materials are used in specialized cases.

Materials are broadly categorized as follows:

Key Considerations for Material Selection:

Properties: Strength, flexibility, chemical resistance, and UV stability vary by material (e.g., ABS for impact resistance, PC for transparency).

Processing: Thermoplastics require temperatures of 180–300°C, while metals need higher pressures.

Sustainability: Many thermoplastics like PP and HDPE are recyclable, reducing environmental impact.