Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What can you make with injection molding?

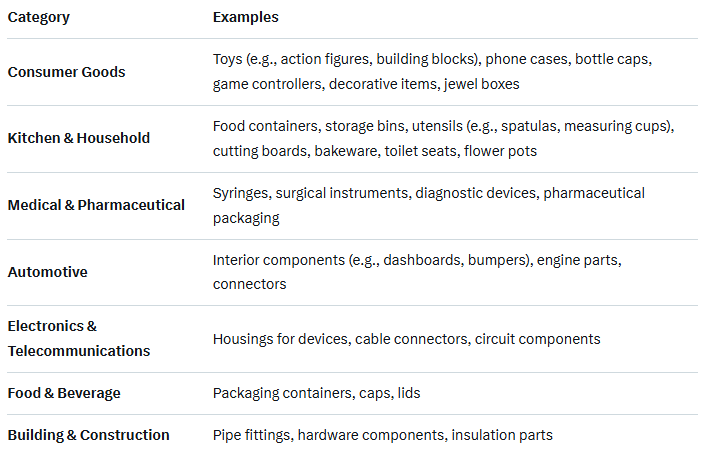

Injection molding is a versatile manufacturing process that injects molten plastic (or other materials like metal or glass) into a mold to create precise, high-volume parts. It's widely used across industries for its efficiency, cost-effectiveness, and ability to produce complex shapes. Below, I'll outline common categories of products made with injection molding, along with specific examples drawn from everyday items.

Virtually any rigid plastic part in high volume can be injection molded, from custom prototypes to mass-produced items like packaging. If you're designing something specific, factors like material choice (e.g., ABS for durability or polypropylene for flexibility) and mold complexity play a big role.