Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What causes cold slug in injection molding?

A cold slug is a small, semi-solidified glob of plastic material that forms at the tip of the injection nozzle or in the runner system during the injection molding process. It occurs when the molten plastic cools prematurely before fully entering the mold cavity, often due to heat loss in critical areas. This defect can lead to incomplete fills, surface imperfections, or contamination in the final part if the slug breaks off and enters the mold.

Primary Causes of Cold Slugs

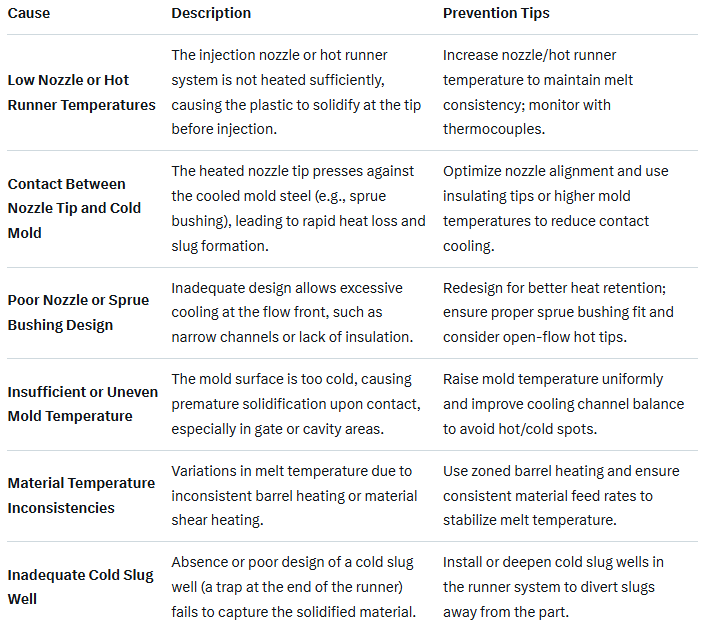

Cold slugs are typically caused by thermal imbalances or design issues that allow the plastic melt to cool too quickly in the flow path. Below is a summary of the most common causes, based on industry insights:

By addressing these factors—primarily through temperature control and mold design optimization—cold slugs can be minimized or eliminated, improving part quality and reducing scrap rates.