Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What causes splay in injection molding?

Splay (also known as silver streaks or splash marks) is a common surface defect in injection-molded plastic parts. It appears as off-color streaks, splashes, or hazy lines on the surface, often resembling burn marks or moisture-related discoloration. This defect occurs when gas bubbles or vaporized materials are dragged along the flow front during the filling stage of the molding process, creating visible imperfections.

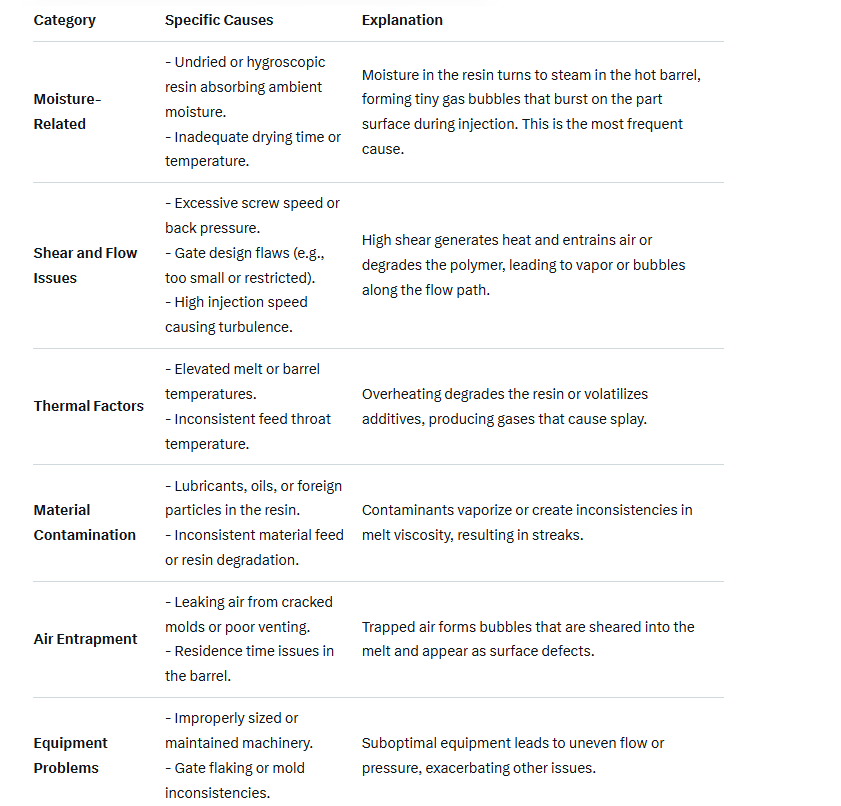

Splay is typically triggered by a combination of material, processing, and equipment factors.

Below is a summary of the most common causes, grouped by category for clarity:

To minimize splay, focus on proper resin drying (e.g., using desiccant dryers), optimizing processing parameters (like reducing shear via slower speeds), and regular equipment maintenance. Testing with small batches can help isolate the root cause.If you're troubleshooting a specific setup, analyzing the defect's location (e.g., near gates) can pinpoint the issue.