Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What causes weld lines in injection molding?

Weld lines (also known as knit lines) are visible lines, seams, or weak points on the surface of an injection-molded plastic part. They form when two or more fronts of molten plastic converge and attempt to fuse together during the filling stage of the molding process. If the fusion is incomplete, it results in a cosmetic defect or a structural weakness, often appearing as a faint line, color change, or notch.

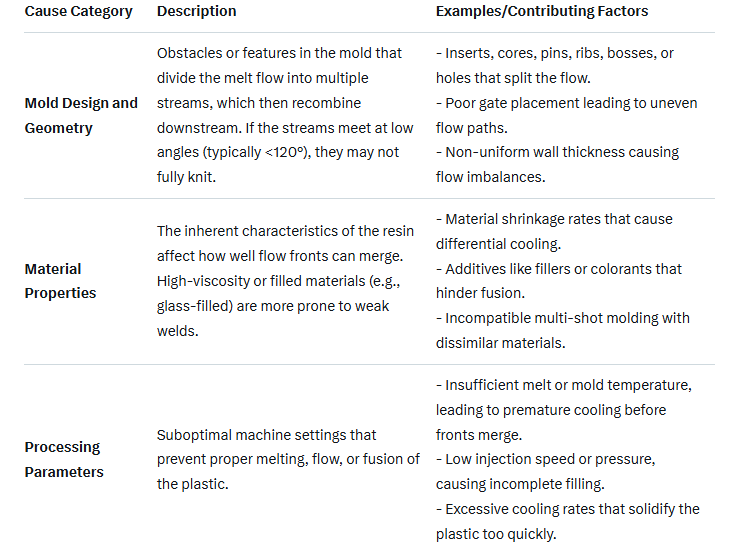

Primary Causes of Weld Lines

Weld lines are primarily caused by the dynamics of molten plastic flow within the mold cavity. Here's a breakdown of the key factors:

These causes often interact—for instance, a complex mold geometry combined with low injection temperature can exacerbate the issue. Weld lines are unavoidable in some designs (e.g., around unavoidable obstacles) but can be minimized through design adjustments, material selection, or process optimization.