Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is a shut off in injection molding?

In injection molding, a shut-off (also called a shut-off surface or shut-off feature) is a critical design element in the mold where the two halves (core and cavity) meet and seal against each other to control the flow of molten plastic. This intersection effectively "shuts off" or blocks material from entering unwanted areas, such as holes, cavities, or beyond the intended part boundaries, while allowing precise filling of the mold cavity.

The primary role of a shut-off is to:

Prevent flash (excess plastic leaking between mold halves under high injection pressure).

Ensure complete and uniform filling of complex geometries, like internal holes or channels, without voids or incomplete enclosure.

Divert or separate molten plastic from the runner (the channel feeding material into the cavity) into the final part shape, enabling efficient material use and high-quality parts.

Without proper shut-offs, issues like overfilling, weak seals, or part defects can occur, especially in multi-cavity molds or when overmolding materials like TPE (thermoplastic elastomers).

Key Design Considerations

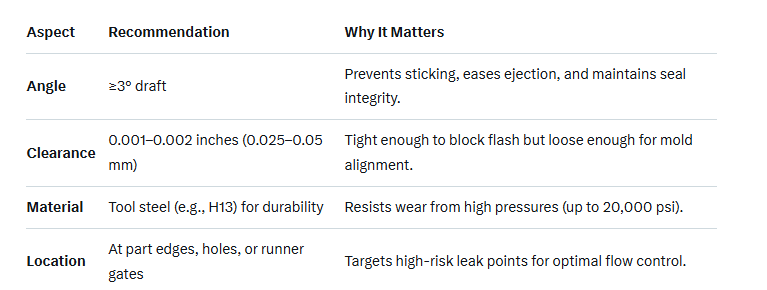

Shut-offs must be engineered carefully to withstand clamping forces and material pressures. Common types and guidelines include:

1.Shut-off surface: The flat or contoured meeting plane between mold halves that creates seamless edges or openings in the part.

2.Shut-off angle: A slight taper (typically at least 3 degrees) at the intersection to avoid mold collisions, reduce wear, and ensure a tight seal during closure.

3.Shut-off nozzle: A valve-like mechanism in the injection unit to prevent drooling (plastic leakage) between shots.

4.Sliding shut-off: Used for dynamic molds with moving parts, but requires low-friction materials to minimize damage from repeated sliding.