Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is cooling time in injection molding?

Cooling time is a critical phase in the injection molding process, referring to the duration required for the molten plastic (or other thermoplastic material) injected into the mold to solidify and reach a temperature where it can be safely ejected without deforming or warping.

This phase typically follows the injection and packing stages and is the longest part of the overall molding cycle, often accounting for 60-80% of the total cycle time.

Why It Matters

Part Quality: Insufficient cooling can lead to defects like shrinkage, sink marks, or internal stresses, while over-cooling wastes time and reduces efficiency.

Cycle Efficiency: Optimizing cooling time directly impacts production speed and cost. Thicker parts require longer cooling, so product design heavily influences this metric.

Process Control: It ensures the part is rigid enough for handling, maintaining dimensional accuracy and surface finish.

Key Factors Influencing Cooling Time

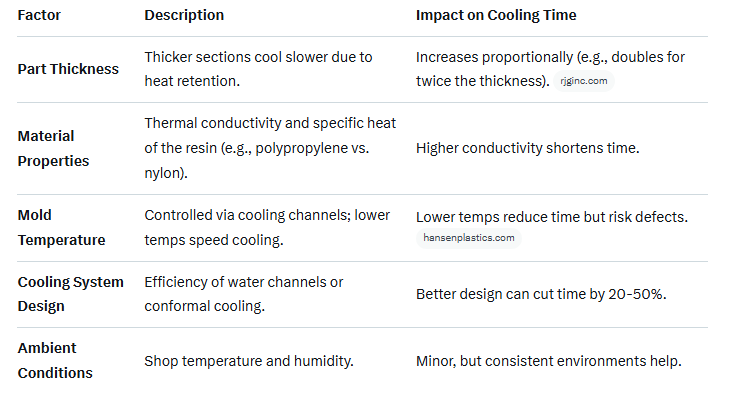

Cooling time depends on several variables, which can be optimized through mold design, material selection, and process parameters.

Here's a summary: