Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is core and cavity in injection molding?

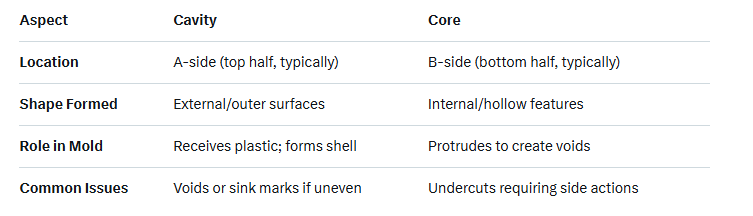

Injection molding is a manufacturing process where molten plastic is injected into a mold to create precise parts. The mold itself is typically divided into two main halves: the A-side (often called the cavity side) and the B-side (often called the core side). These halves come together to form the complete mold cavity, which defines the shape of the final part. The key components here are the core and cavity, which work together to shape both the external and internal features of the molded product.

What is the Cavity?

The cavity is the negative space (or hollow impression) in the mold that receives the injected molten plastic.

It primarily forms the exterior surface and overall outer dimensions of the part.

Typically located on the A-side of the mold, it's the "female" portion where the plastic flows in and solidifies against its walls.

What is the Core?

The core is the protruding or male portion of the mold that inserts into the cavity.

It forms the internal surfaces, such as holes, undercuts, or recessed features in the part.

Usually positioned on the B-side, it often includes ejector pins to push the finished part out after cooling.

How They Work Together

When the mold closes, the core aligns precisely with the cavity, creating a sealed space that matches the part's geometry.

Molten plastic fills this space under high pressure, cools, and hardens to replicate the mold's shape.

Proper design of core and cavity placement is crucial for part quality, as it affects factors like draft angles, cooling efficiency, and ejection.