Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is draft angle injection molding?

In injection molding, a draft angle (also called draft) is a slight taper or angle applied to the vertical walls or faces of a molded part, typically ranging from 0.5° to 2° relative to the mold's opening direction. This design feature ensures the part can be easily ejected from the mold after cooling, preventing damage to the part or mold. Without sufficient draft, the solidified plastic can stick to the mold cavity, leading to defects like scratches, cracks, or incomplete parts.

Why is Draft Angle Important?

1.Easier Demolding: It reduces friction between the part and mold, allowing for smoother release without excessive force.

2.Improved Part Quality: Minimizes surface imperfections and wear on the mold over production runs.

3.Cost Efficiency: Reduces the need for mold release agents or complex ejection systems, speeding up cycle times.

Draft is especially critical for deep cavities, tall sidewalls, or textured surfaces, where sticking is more likely.

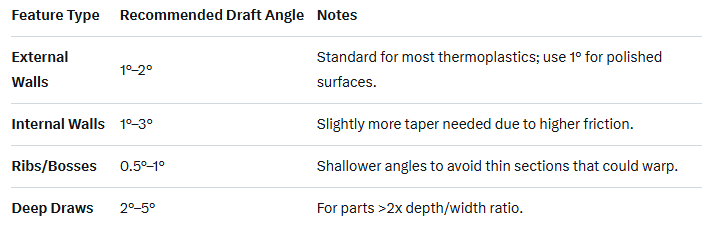

Guidelines for Draft AnglesDraft requirements vary by material, part geometry, and surface finish. Here's a general rule of thumb based on common practices: