Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to cast metal?

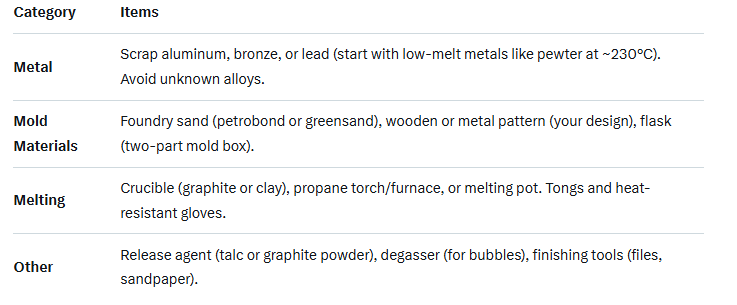

Materials and Tools Needed:

Step-by-Step Process for Basic Sand Casting:

1.Design and Create the Pattern

Carve or 3D-print a pattern of your object (slightly larger to account for shrinkage, ~1–2%). Include a sprue (pouring hole) and risers (vents for gases).

2.Prepare the Mold

Pack damp sand around one half of the pattern in the flask bottom.

Add the top flask, pack sand around the other half, and separate.

Remove the pattern carefully, creating the cavity. Dust with release agent.

Reassemble the flasks and secure.

3.Melt the Metal

Place metal in the crucible and heat gradually in a furnace or over a torch until fully molten (test with a pyrometer or by stirring).

Skim off impurities (dross). Add flux if needed to reduce oxidation.

Maintain temperature; avoid overheating to prevent gas absorption.

4.Pour the Metal

Use tongs to lift the crucible.

Pour steadily into the sprue, filling the cavity completely (tap gently to release air bubbles).

Fill risers last to compensate for shrinkage.

5.Cool and Demold

Let cool undisturbed for 30–60 minutes (or until solid; time varies by metal size).

Break away the sand mold.

Remove the casting from the flask.

6.Finish the Casting

Cut off sprue/risers with a hacksaw.

File/sand/grind rough edges.

Polish or heat-treat if desired for strength.