Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to make a casting mold for metal?

Sand casting is one of the oldest and most accessible methods for creating metal molds at home or in a small workshop. It involves packing damp sand around a pattern (a model of your desired object) to form a cavity, which is then filled with molten metal. This technique works well for aluminum, bronze, or low-melting alloys like bismuth, but it's best for simple shapes due to the mold's single-use nature. The process is DIY-friendly but requires caution with heat and sand handling. Always prioritize safety, as molten metal can cause severe burns.

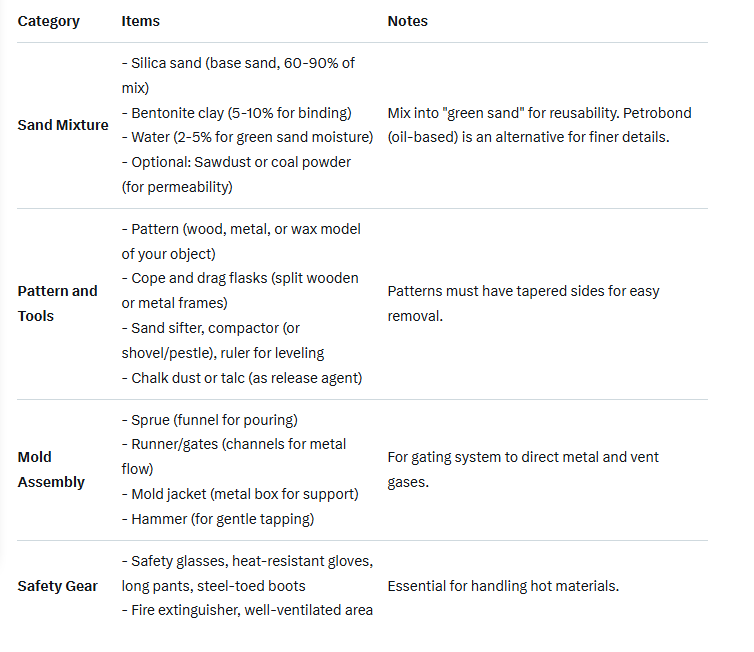

Materials Needed:

Step-by-Step Guide to Making the Mold

This synthesizes a standard green sand process for a two-part mold (cope and drag halves). It assumes a simple pattern; complex shapes may need cores for internal voids.

1.Prepare the Sand Mixture

Combine silica sand, bentonite clay, and water in a 90:8:2 ratio (adjust for moisture—sand should hold shape when squeezed but not drip). Mix thoroughly until uniform. Sift to remove lumps. Let it rest for 10-15 minutes. This "green sand" provides strength and reusability.

2.Set Up the Drag (Bottom Half)

Place your pattern on a flat pattern plate (e.g., plywood) with the flat side down.

Dust the pattern lightly with chalk or talc to prevent sticking.

Position the drag flask (bottom frame) over the pattern.

Sift sand into the flask, filling it evenly. Compact firmly in layers (use a compactor or rammer) from edges to center, ensuring no air pockets—tight packing prevents defects.

Level the top surface with a ruler. Add vent holes (small oblique holes ~40mm apart) for gas escape.

Carefully flip the drag 180 degrees to expose the pattern cavity.

3.Create the Cope (Top Half)

Align the pattern's top half (if split) or the full pattern extension on the drag. Secure the cope flask (top frame) to the drag using aligning pins.

Cut or form the sprue (tapered funnel hole) at one end for pouring, and runners/gates leading to the cavity. Add a pouring basin if needed.

Sift and compact sand into the cope as in Step 2. Level the top.

Gently separate the cope from the drag.

4.Remove the Pattern

With drag and cope aligned, slowly lift the cope off.

Smooth any rough edges in the cavity with a tool.

Carefully extract the pattern vertically (wiggle if stuck, but avoid damaging walls). Dust again if reusing.

If your casting has internal features, insert pre-made sand cores now (paint and dry them first for strength).

5.Assemble the Mold

Clean debris from cavities.

Align and clamp the cope onto the drag precisely (use pins for accuracy).

Place in a mold jacket for stability.

Inspect for gaps—add sand if needed. The mold is now ready for pouring molten metal (melt in a kiln or ladle, skim oxides, pour steadily).

6.Post-Casting (After Pouring and Cooling)

Let metal solidify (1-2 hours depending on size).

Break the mold with a hammer, dig out the casting, and quench in water if safe. Clean and file excess.

Reuse sand by drying and remixing.