Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Can you use clay for metal casting?

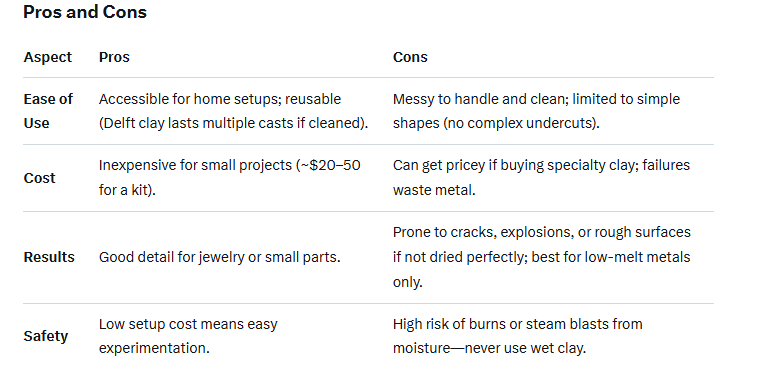

Yes, clay can be used for metal casting, particularly in small-scale or DIY projects like jewelry or prototypes, but it's not the most straightforward or risk-free method compared to sand or plaster molds. Success depends on using the right type of clay, thorough drying to eliminate moisture (which can cause steam explosions or cracking), and compatibility with lower-melting metals like aluminum or bronze. Regular pottery clay is generally discouraged due to its high water content, but specialized clays work well. Below, I'll break it down.

Suitable Types of Clay

Delft Clay: A fine, reusable molding clay designed specifically for metal casting. It's packed into frames to create two-part molds and is popular for beginners because it's affordable and forgiving for simple shapes.

Polymer Clay (e.g., Sculpey): A non-traditional "clay" that hardens when baked. It's ideal for quick prototypes but has a low heat tolerance (around 385°F/196°C), so it's best paired with low-melt metals.

Basic Process for Clay Metal Casting:

Here's a simplified overview, combining common techniques (always prioritize safety gear like gloves, goggles, and a respirator):

1.Design and Prepare the Model: Carve or 3D-print a durable pattern (e.g., from wax or resin) without undercuts for easy demolding.

2.Build the Mold: Pack clay into a frame (wood or metal) to form the first half, embed the model, then create the second half. Dust with talc or charcoal powder to prevent sticking.

3.Carve Channels and Vents: Remove the model, then etch a pour spout and air vents into the clay to allow metal flow and gas escape.

4.Dry the Mold Thoroughly: Fire in a kiln or furnace to remove all moisture—air-drying isn't enough and risks explosions.

5.Melt and Pour: Heat compatible metal (e.g., aluminum at ~1,200°F/650°C) with flux for clean flow, then pour into the mold.

6.Cool and Finish: Let solidify, break away the clay, cut excess, sand, and polish the casting.

In summary, clay casting is viable for hobbyists but requires practice. If you're new, start with Delft clay kits and aluminum. For professional work, consider sand casting instead.