Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Can you use kinetic sand for metal casting?

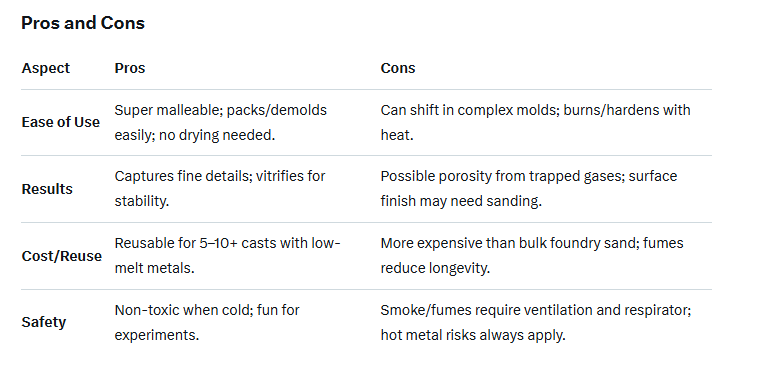

Yes, you can use kinetic sand for metal casting, particularly for low-melting-point metals like pewter, and it has even been successfully tested with higher-melting-point ones like aluminum. However, it's not a perfect substitute for traditional foundry sand (like greensand or petrobond), and it comes with some caveats around fumes, reusability, and safety.

Why It Works

Kinetic sand (typically 98% fine silica sand bound with 2% polydimethylsiloxane, a silicone polymer) is highly malleable, holds fine details well when compacted, and doesn't dry out like regular sand during molding. When heated by molten metal, it tends to vitrify (turn glassy) rather than break down thermally, which helps maintain mold integrity. This makes it great for simple, open-face or single-part molds, and it's reusable— you can often brush off the cast and repack it multiple times without much loss of cohesion, especially with low-melt alloys.

Limitations and Potential Issues

1.Burning and Fumes: The silicone binder can burn during pouring, releasing acrid smoke (described as "burnt pork," "road tar," or "moldy fart") and potentially toxic vapors. This hardens the sand locally and makes it less reusable over time. It's comparable to fumes from standard casting sands like petrobond, but still unpleasant—many users say the metal melt itself (especially zinc or brass alloys) produces worse, invisible toxins.

2.High-Melt Metals: Works best below 700°F (e.g., pewter at 450–500°F). For aluminum (1200°F) or higher, the sand may dry out, crack, or require more compaction, and reusability drops.

3.Mold Complexity: Excellent for open or simple one-sided molds, but too fluid for closed, multi-part molds without additives or frames— it can shift under pour pressure.

4.Not Professional-Grade: Fine for hobbyists or prototypes, but traditional sands are cheaper and more consistent for production.