Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to cast small metal and rubber parts?

Casting small metal parts is a rewarding DIY process for creating custom items like jewelry, tools, or model components. It's accessible for beginners with basic equipment, but it involves high temperatures (up to 1,200°C/2,200°F), so prioritize safety. Common methods for small parts include sand casting (simple and low-cost for prototypes) and lost-wax casting (precise for intricate designs).

Safety Tips

1.Always wear leather gloves, thick leather boots, protective goggles or a face shield, and long sleeves.

2.Work in a well-ventilated outdoor area or with fume extraction to avoid inhaling fumes.

3.Use a fire extinguisher rated for metal fires (Class D) nearby.

4.Never leave melting metal unattended, and avoid melting coated metals like soda cans (they release toxic gases).

5.Let molds cool fully before handling to prevent burns.

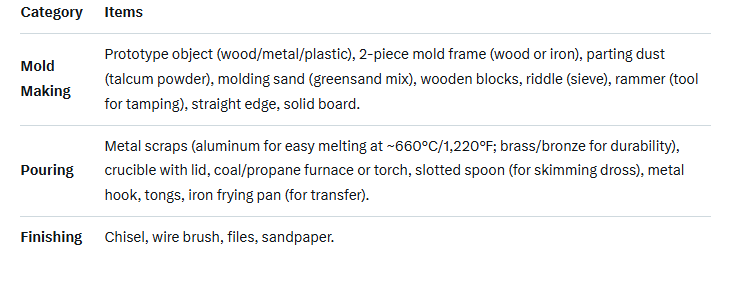

Materials Needed:

Step-by-Step: Sand Casting Small Metal Parts

1.Prepare the Prototype: Create or select a small object (e.g., a gear or pendant) as your pattern. Coat it lightly with parting dust to prevent sticking.

2.Build the Mold: Place the flattest side of the prototype in the bottom half of the mold frame on a flat surface. Mix molding sand with water to a damp paste (prepare 12 hours ahead for best results). Sift sand over the prototype using a riddle, then tamp it down lightly with your fingers. Add more sand above the frame and tamp firmly with a rammer. Smooth the top with a straight edge.

3.Create the Second Half: Sprinkle parting dust on the smoothed surface, cover with a board, and flip the frame. Repeat the sifting and tamping in the top half. Carefully separate the frames and remove the prototype to leave a cavity.

4.Add Pouring Channels: Insert a dowel rod vertically for a sprue (pour hole, ~0.5 cm wide). Chisel a horizontal in-gate from the sprue to the cavity. Add riser holes (vents for excess metal) connected to the cavity.

5.Melt the Metal: Load metal scraps into the crucible and heat in a furnace until fully molten (skim off impurities/dross with a slotted spoon). For small parts, aluminum melts quickly in 10-15 minutes.

6.Pour the Metal: Reassemble and secure the mold. Use tongs and a hook to transfer the crucible to a frying pan, then pour steadily into the sprue until metal rises in the risers (indicating it's full). Pour leftovers into an ingot mold.

7.Cool and Demold: Let cool 20-30 minutes (faster for tiny parts). Break apart the sand mold, remove the casting, and brush off residue.

8.Finish: File gates/risers, sand smooth, and polish as needed.