Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to repair broken cast metal?

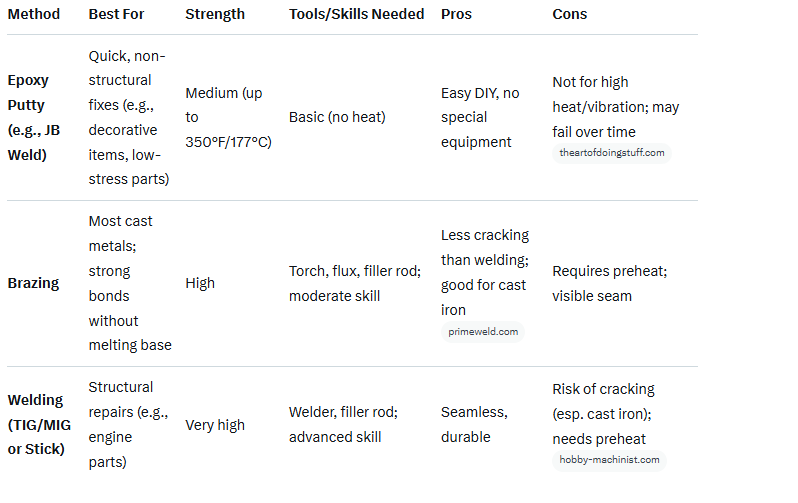

Repairing broken cast metal (like cast iron skillets, engine blocks, or aluminum die-cast parts) depends on the metal type, the break's severity, and the item's intended use. Cast iron is brittle and heat-sensitive, making welding tricky, while cast aluminum is more forgiving but requires clean surfaces. For load-bearing or high-heat applications (e.g., cookware or machinery), opt for brazing or welding over adhesives.

Here's a comparison of common methods:

1. Epoxy Putty Repair (No Heat Required)

Steps:

A.Clean the surfaces: Remove rust, paint, grease, or debris with sandpaper/file. Wipe with acetone to degrease. For aluminum, scuff shiny areas.

B.Mix the putty: Knead a golf-ball-sized piece until uniform color (about 1-2 minutes; it may warm up).

C.Apply: Press into the crack/gap, overlapping edges by 1/4 inch. Overfill slightly for sanding later. Hold pieces aligned (use clamps if needed) for 5 minutes as it sets.

D.Cure: Let harden 1 hour (full cure: 24 hours for best strength). Sand smooth.

F.Test: Gently stress-test; avoid extreme heat initially.

2. Brazing Repair

Steps (Cast Iron Example):

A.Prep: Grind/V-groove the crack to clean metal. Drill stop-holes at ends to prevent spreading. Brush off residue.

B.Preheat: Heat the piece evenly to 500-800°F (dull red) with a neutral flame—slowly, to avoid cracks.

C.Apply flux and braze: Coat crack with flux. Touch rod to hot metal; it melts and flows in. Build up layers, feathering edges.

D.Cool slowly: Let air-cool (no quenching) to minimize stress.

Finish: Grind smooth; test for leaks/cracks.

3. Welding Repair

A.Steps (General):Prep: Clean thoroughly (acetone, grind to bare metal). V-groove crack; preheat iron to 500°F.

B.Weld: Short passes, low heat. Butter edges first for Al.

C.Cool: Slow cool under blanket for iron.

D.Inspect/Finish: X-ray if critical; grind smooth.