Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is casting in metal work?

Casting is a fundamental manufacturing process in metalwork used to create complex shapes by pouring molten metal into a mold, where it cools and solidifies into the desired form. It's one of the oldest and most versatile methods for shaping metals, dating back thousands of years, and is widely used today in industries like automotive, aerospace, jewelry, and construction to produce parts ranging from engine blocks to intricate sculptures.

Key Steps in the Casting Process

The process typically involves the following stages:Pattern Creation: A reusable model (pattern) of the final part is made from wood, plastic, or metal, slightly oversized to account for shrinkage.

Mold Preparation: The pattern is placed in a molding material (like sand, plaster, or ceramic) to form a cavity. For reusable molds, materials like graphite or metal are used.

Melting and Pouring: The metal (e.g., aluminum, iron, steel, or bronze) is heated to its melting point in a furnace and poured into the mold through a gating system (channels that direct flow and prevent defects).

Solidification and Cooling: The molten metal cools and hardens, taking the shape of the mold cavity.

Mold Removal and Finishing: The solidified casting is extracted, excess material (sprues, risers) is removed, and the part is cleaned, machined, or heat-treated as needed.

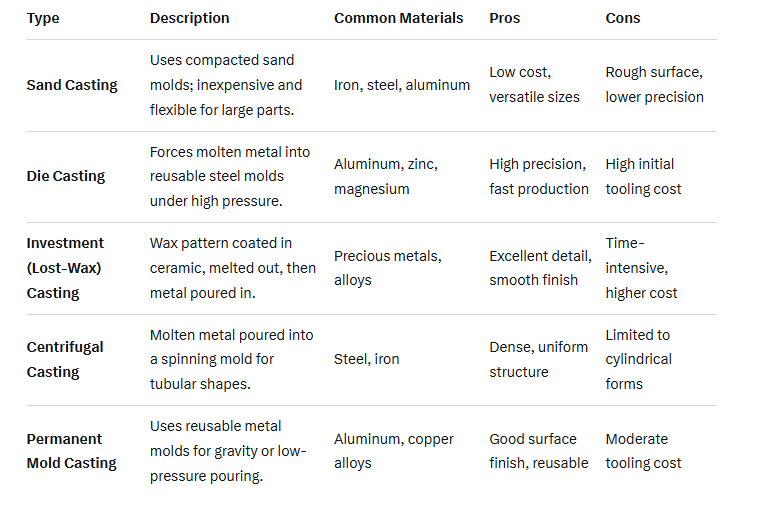

Common Types of Casting

Different techniques suit various scales, materials, and precision needs. Here's a comparison: