Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to clean 3d printer bed?

Here’s a complete, reliable guide to cleaning your 3D printer bed properly. The exact method depends on your bed surface type (most common ones listed).

1. Identify Your Bed Surface

PEI sheet (smooth or textured) – most common on modern printers (Prusa, Bambu, Creality, etc.)

Glass bed (bare or with coating)

Magnetic flex plate (e.g., Wham Bam, BuildTak flex plates)

G10 / Garolite (for nylon)

Old-school BuildTak / LokBuild / painter’s tape

2. Daily / Regular Cleaning (First Layer Issues or Light Dirt)

For PEI, textured/smooth sheets, and most coated beds:

a.Wait until the bed is room temperature or just slightly warm (never clean when hot — you can damage the coating).

b.Use isopropyl alcohol (IPA) 70–99% and a clean microfiber cloth or paper towel.

c.Wipe in circles, flip the cloth often. If stubborn spots remain, let the IPA sit for 30–60 seconds then wipe.

d.For extra grip recovery on PEI: after IPA, wash with warm water + a few drops of dish soap (Dawn, Fairy, etc.), using a new sponge (no abrasive side). Rinse thoroughly, dry with a clean towel or let air dry. Do this every 10–20 prints or when first layer stops sticking well.

3. Heavy Contamination (Filament stuck, oils, grease)

PEI / coated sheets:Scrape gently with a plastic scraper or old gift card while bed is warm (~60–70 °C).Then IPA wipe.If still bad: dish soap wash (as above).Last resort: very fine wet sanding with 2000–3000 grit (only if the sheet is ruined anyway).

Glass beds:Warm bed → plastic scraper → IPA or window cleaner.Acetone is safe on bare glass if you used ABS juice or glue stick residue.

BuildTak / similar:Scrape carefully, then IPA. These wear out; replace when damage.

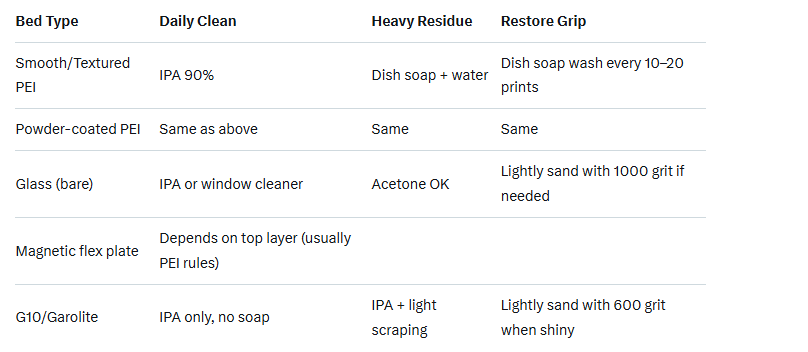

4. Quick Cheat Sheet by Material