Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to smooth 3d prints?

Smoothing 3D prints is a very common post-processing step to remove layer lines and get a glossy, professional finish. The best method depends on your filament type, desired finish, safety setup, and how much time/effort you want to spend.

Here are the most effective and popular methods, ranked roughly from easiest/safest to more advanced:

1. Sanding (Works on ALL materials: PLA, ABS, PETG, ASA, etc.)

Best for: Any print, especially when you want full control.

2. Vapor Smoothing with Acetone (ABS & ASA only!)

Best for: Getting injection-molded-like glossy finish on ABS/ASA.How it works: Acetone vapor melts the outer layer slightly, making it flow and remove layer lines.

3. Chemical Smoothing for PLA

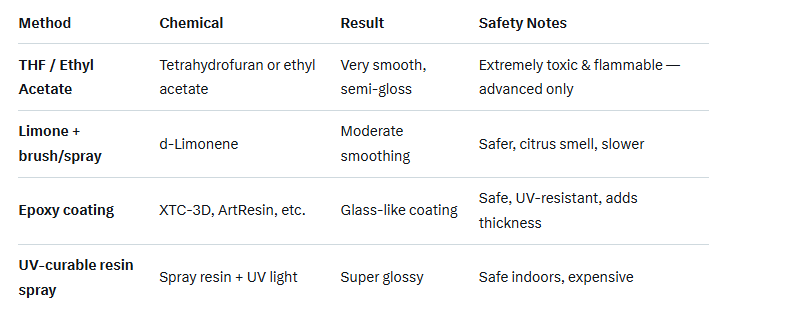

PLA doesn’t react to acetone, but these alternatives work:

Most people now prefer epoxy or resin coating over solvent dipping because they’re safer and give better results on PLA.

4. Epoxy/Resin Coating (Best all-round method for PLA & PETG)

Products: XTC-3D (Smooth-On), Alumilite Amazing Clear Cast, any 2-part epoxy, or spray-on clear coat (2K automotive clear).

5. Filler Primer + Sanding (Great for painted prints)