Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is a good wall thickness for 3d printing pla?

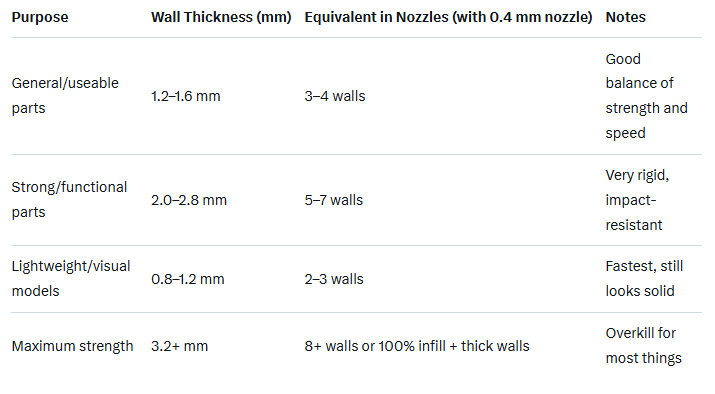

A good wall thickness for 3D printing with PLA depends on your goals (strength, print time, material usage), but here are the most common and recommended values:

Standard Recommendations

Rule of Thumb :

Most People UseUse a wall thickness that is a multiple of your nozzle diameter.With the common 0.4 mm nozzle → multiples of 0.4 mm (0.8, 1.2, 1.6, 2.0, 2.4 mm, etc.) give the cleanest, most consistent walls.

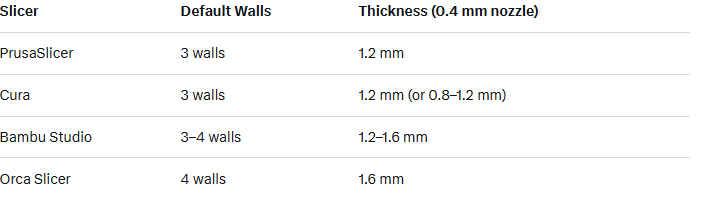

Popular Default Settings in Slicers

When to Choose :

1.2 mm (3 walls) → 90 % of prints. Looks good, strong enough for most things, prints reasonably fast.

1.6 mm (4 walls) → Slightly stronger, nicer outer surface, very popular for functional parts.

2.0+ mm → Mechanical parts, tools, brackets, anything that will see real stress or impact.

0.8 mm (2 walls) → Quick prints, prototypes, display models where strength isn’t critical.

Bonus Tips for

PLA is brittle, so more walls (or higher infill) helps a lot more than with tougher filaments like PETG or ABS.

If you want thin but strong parts, combine 2–3 walls with 15–25 % gyroid or cubic infill instead of going super thick on walls.

For vases or single-perimeter objects (“vase mode”), you usually use exactly 1 wall (0.4–0.6 mm) on purpose.