Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Can you 3d print o rings?

Yes, we can 3D print O-rings.

When 3D-printed O-rings work well

Prototyping or low-pressure/static seals (e.g., enclosing electronics, decorative parts, very low-pressure air or water)

One-off custom sizes that are expensive or impossible to buy off-the-shelf

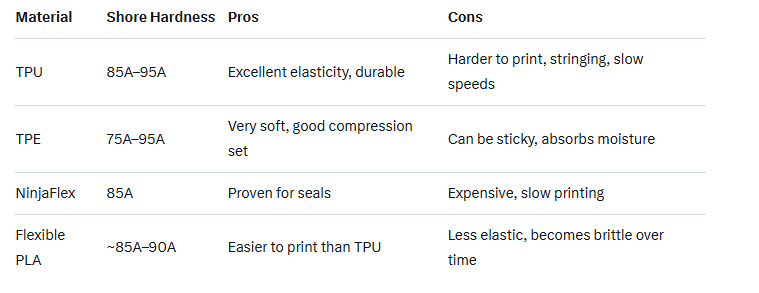

Materials like TPU, TPE, or flexible PLA (NinjaFlex, Cheetah, FlexiFil, etc.)

Common flexible 3D printing filaments for O-rings

Why 3D-printed O-rings are usually not ideal for real sealing applications

a.Layer lines = leak paths

Even with 0.1 mm layers and 100% infill, microscopic gaps between layers let fluid or gas seep through under pressure.

b.Poor compression set

Most flexible filaments slowly take a permanent “set” when compressed for days/weeks. A real O-ring (made of Nitrile, Viton, Silicone, etc.) recovers almost perfectly.

c.Chemical/temperature resistance

3D printer filaments dissolve or swell in oils, fuels, solvents, or hot water. Real O-ring materials are engineered specifically to resist these.

d.Surface finish

Injection-molded O-rings are glass-smooth. 3D-printed ones are rough unless you post-process (tumble, vapor smooth, coat with silicone, etc.).

Practical tips if you still want to print them

a.Use 95A–98A TPU (closer to real O-ring hardness; 85A is too soft for most grooves)

b.Print at 0.1–0.15 mm layer height, 100% infill, 4–6 perimeters

c.Slightly undersize the inner diameter by 2–5% so it has to stretch into the groove (improves sealing)

d.Print slowly (20–30 mm/s) and use direct-drive extruder if possible

e.Lightly coat with silicone grease or liquid silicone after printing to fill layer lines.