Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How strong is 3d printed material?

The strength of 3D-printed parts varies enormously — from “weaker than cheap packaging foam” to “stronger than machined aluminum” — depending on several key factors. Here’s a practical breakdown:

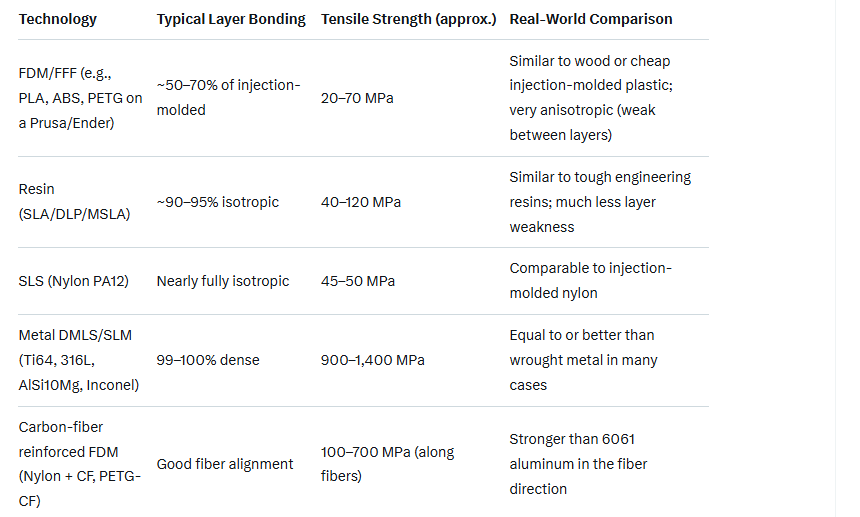

1. Printing Technology Matters Most

2. Layer Adhesion = The Achilles’ Heel of FDM

In consumer FDM, parts are typically only 30–70% as strong between layers as within a layer. A 60 MPa PLA part printed with good settings might fail at only ~20–30 MPa if you pull perpendicular to the layers (like peeling apart a lasagna).

Tricks to dramatically improve FDM strength:

a.Use high-temperature materials (ASA, PC, Nylon) and a heated chamber or enclosure → can reach 80–90% layer bonding

b.Anneal the part after printing (e.g., 110 °C for PLA, 90–120 °C for Nylon)

c.Print slower, hotter nozzle, higher bed temp

d.Use 100% infill + many perimeters or gyroid infill

e.Add continuous carbon-fiber (Markforged, Anisoprint) → parts can hit 700+ MPa in fiber direction, rivaling aluminum

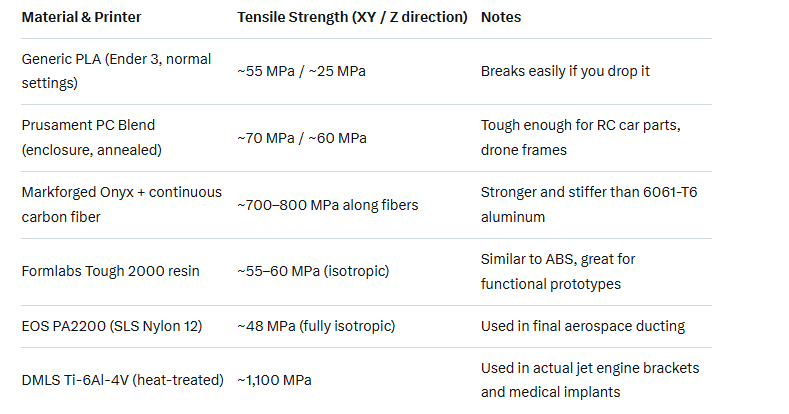

3. Real-World Examples (tested values)