Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to get better adhesion 3d printer?

To get significantly better bed adhesion on your 3D printer (and fewer failed prints), focus on these key areas in order of biggest impact:

1. Choose the Right Bed Surface for Your Filament

→ Most people see the single biggest jump by switching to a good spring-steel textured PEI sheet (e.g., Prusa, WhamBam, or genuine PEO/PEI sheets). They stick like crazy and parts pop off easily when cool.

2. Perfect Your First Layer

a.Bed must be perfectly level/trammed (use mesh bed leveling if your printer has it — Klipper, Prusa, Bambu, etc.).

b.Live Z (nozzle height) is everything. The first layer should look slightly squished, almost like the lines are touching or merging, not round spaghetti strands.

c.Do a proper “paper test” or, better, a live first-layer calibration print (search “first layer calibration test” on Printables or Thingiverse).

Slow the first layer down to 15–30 mm/s.

3. Clean the Bed Properly

a.Wash with warm water + dish soap (Dawn/Fairy) and dry with a clean microfiber every 5–10 prints.

b.For stubborn grease: 99% isopropyl alcohol (IPA) on a lint-free cloth).

c.Never touch the bed with bare hands after cleaning.

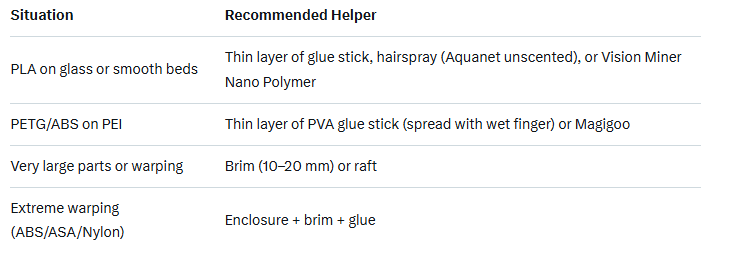

4. Use Adhesion Helpers When Needed

5. Temperature Tweaks

a.Increase bed temperature 5–10 °C higher than usual for the first few layers (e.g., PLA 65 °C instead of 60 °C).

b.Slightly increase nozzle temperature for the first layer (+5–10 °C) → better flow and squish.

6. Mechanical & Environmental Fixes

a.Eliminate drafts (cover printer or add enclosure panels).

b.Keep filament dry — wet filament causes warping and poor adhesion.

c..Add a brim or mouse ears on corners for big parts.

d..Use an adhesion promoter like Magigoo, 3DLac, Dimafix, etc. for problem filaments.