Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is zinc die cast?

Zinc die casting is a metal casting process that involves forcing molten zinc alloy under high pressure into a reusable steel mold (called a "die"). It is one of the most efficient and cost-effective ways to produce high-volume, high-precision metal parts with excellent surface finish and dimensional accuracy.

Key Features of Zinc Die Casting

a.Materials used: The most common alloys are Zamak (Zamak 3, Zamak 5, Zamak 7), ZA-8, ZA-12, ZA-27, and ACuZinc. Zamak 3 is the most widely used because of its balance of strength, ductility, and castability.

b.Process types:

Hot-chamber die casting (most common for zinc): The metal is melted in a furnace attached to the machine, and a gooseneck plunger injects it into the die. Very fast cycle times (15–90 seconds).

Cold-chamber die casting (rarely used for zinc, more common for aluminum/magnesium).

Advantages of Zinc Die Casting

a.Extremely fast production (hundreds to thousands of parts per hour)

b.Very tight tolerances (±0.001–0.002 in or ±0.025–0.05 mm)

c.Thin wall capability (down to 0.015 in / 0.38 mm in some cases)

d.Excellent surface finish – often requires little or no secondary finishing

e.Superior EMI/RFI shielding (great for electronic housings)

f.High strength and hardness compared to aluminum or magnesium die castings

g.Long die life (often 1 million+ shots)

h.Can cast complex shapes, undercuts, and fine details

i.Fully recyclable

Typical Applications

a.Automotive: door lock housings, seat belt parts, fuel system components

b.Electronics: connector bodies, shields, chassis for routers/modems

c.Consumer goods: zipper sliders, bathroom fixtures, power tool housings

d.Builders’ hardware: locks, hinges, handles

e.Medical devices and instruments

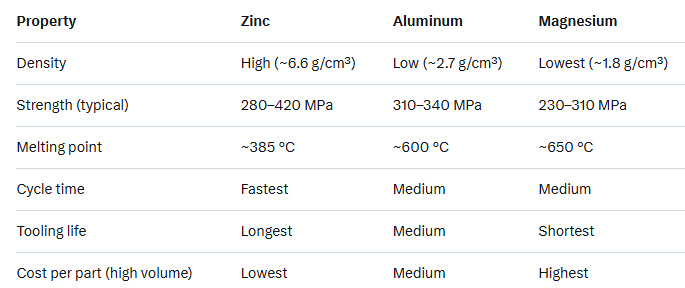

Comparison with Other Die-Casting Materials