Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How strong is die cast zinc?

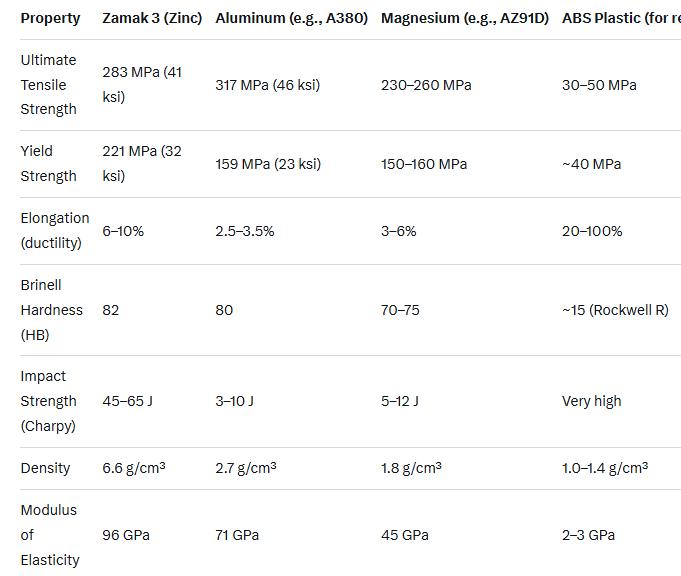

Die-cast zinc (typically alloys like Zamak 3, Zamak 5, or ZA-8) is one of the strongest and hardest materials commonly used in high-pressure die casting. Here's a breakdown of its mechanical properties compared to other common die-casting materials:

Key Mechanical Properties (typical values for Zamak 3, the most common zinc die-casting alloy)

Summary: How Strong Is Die-Cast Zinc?

a.Stronger and harder than aluminum and magnesium die-casting alloys in most respects (higher yield strength, hardness, and impact resistance).

b.Significantly stronger and stiffer than engineering plastics.

Excellent wear resistance and dent resistance — zinc parts resist deformation and scratching much better than aluminum or magnesium.

c.Good fatigue strength for its class.

d.Lower ductility than magnesium or plastics — it is more brittle (can crack under severe bending or high impact), but still far better than cast iron or many aluminum alloys.

Practical Implications

a.Ideal for small, intricate, thin-walled parts that need strength, precision, and good surface finish (e.g., hardware, locks, gears, connectors, carburetor bodies, hand tools, zippers).

b.Heavier than aluminum or magnesium (about 2.4× denser than Al), so not used where weight is critical.

c.Superior threading and self-tapping screw retention due to high hardness.