Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What are vacuum casting prototyping?

Vacuum casting (also called urethane casting or silicone mold casting) is a rapid prototyping and low-volume production technique used to create high-quality plastic parts that closely mimic injection-molded components, but at a much lower cost and lead time than hard tooling.

How Vacuum Casting Works (Step by Step)

1.Master Pattern

A high-quality master model is created (usually via CNC machining or 3D printing – SLA or high-resolution PolyJet is common because of the surface finish is excellent).

2.Silicone Mold Making

The master pattern is suspended in a box. Liquid silicone rubber is poured around it and cured (often under vacuum to eliminate air bubbles). After curing, the silicone block is cut along a predefined parting line and the master pattern is removed → this leaves a flexible, highly detailed silicone mold.

3.Casting the Parts

The silicone mold is reassembled and placed in a vacuum chamber.

Two-component polyurethane (PU) resin is mixed, degassed under vacuum, and poured into the mold (still under vacuum). Vacuum removes air bubbles and ensures the liquid resin fills even the finest details and thin walls. The mold is then cured in an oven (typically 60–80°C) for 30 min to a few hours.

4.Demolding & Finishing

The cured part is removed from the flexible silicone mold.Gates/sprues are cut off, and parts can be painted, textured, inserted with metal threads, dyed, etc.

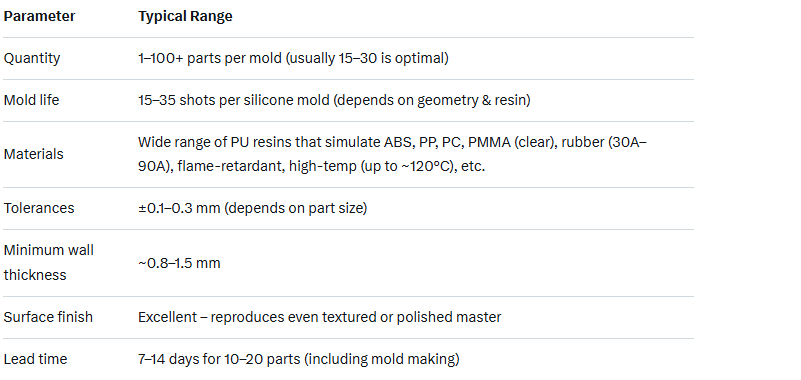

Typical Specifications & Capabilities

Very high cosmetic quality and detail reproduction

1.Wide choice of material properties (rigid, flexible, transparent, colored, etc.)

2.Much cheaper and faster than aluminum/steel injection mold tooling for quantities < ~500–1000

3.Overmolding and insert molding possible (e.g., soft TPE over rigid part)

4.Transparent parts can be cast and polished to optical clarity

Limitations

1.Mold degrades after 15–35 shots → not suitable for thousands of parts

2.Material properties are close but not 100% identical to real injection-molded thermoplastics

3.Slightly higher per-part cost than mass production injection molding

Common Applications

1.Concept models & marketing samples

2.Functional prototypes for testing (snap fits, living hinges, etc.)

3.Pre-production and bridge tooling (before committing to hard tooling)

4.Low-volume end-use parts (medical devices, consumer electronics housings, automotive interiors, etc.)

5.Clear lenses, light pipes, and transparent covers

In short, vacuum casting is one of the most popular prototyping methods when you need 5–50 near-production-quality plastic parts quickly and economically.