Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is the Turning-milling composite processing technology?

Turning-milling composite processing (also called mill-turn machining, multi-tasking machining, or complete machining) is an advanced CNC machining method that integrates turning and milling (and often other processes) on a single machine tool to complete most or all machining of a workpiece in one setup.

Core Concept

Traditional process: A part might go through a lathe (turning) → machining center (milling) → grinding machine, requiring multiple setups and machine changes.

Turning-milling composite: One machine has both a rotating spindle (for milling/drilling) and a rotating workpiece axis (C-axis or B-axis with swiveling spindle), plus a tool turret or magazine that can hold live tools (rotating milling cutters). The machine can switch seamlessly between turning and milling operations.

Main Types of Turning-Milling Composite Machines

1.Turning-center-based (most common)

Main spindle holds and rotates the workpiece (like a conventional lathe)

Equipped with live tooling (powered rotating tools) on the turret

Usually has Y-axis and sometimes B-axis (swivel head)

Typical models: Mazak Integrex, DMG MORI NTX/NTC series, Okuma Multus, Doosan Puma SMX, etc.

2.Milling-center-based

Workpiece is fixed on a table, spindle does turning by rotating special turning tools

Less common, mainly used for very large parts

3.Full 5-axis mill-turn machines

(Integrex i-series, CTX gamma, etc.)Simultaneous 5-axis milling + turning capability

Can machine extremely complex geometries (impellers, turbine blades, etc.) in one setup

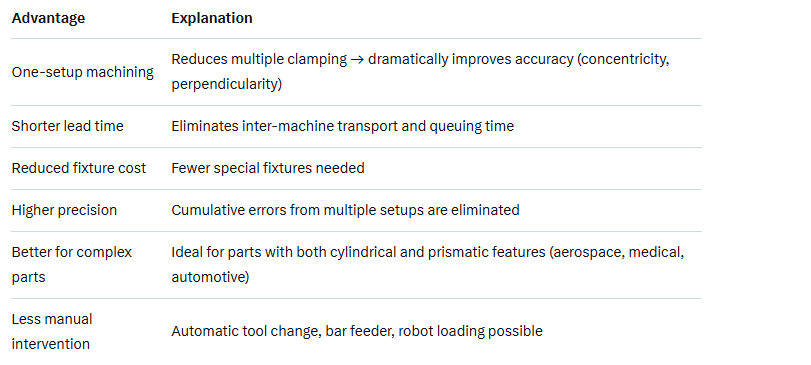

Key Advantages

Typical Processes

1.That Can Be Done on One MachineExternal/internal turning

2.Milling (contouring, pockets, complex surfaces)

3.Drilling, tapping, boring

4.Deep-hole drilling (with gun drill tools)

5.Gear hobbing, spline cutting

6.Grinding (some high-end machines have grinding spindles)

7.Part transfer between main and sub-spindle (for 6-sided complete machining)

Representative Machine Layout (example: common dual-spindle + B-axis type)

1.Upper turret: 12–24 stations with live tools + Y-axis

2.Lower turret (optional)

3.Main spindle (C1) + sub-spindle (C2) for part handover

4.B-axis swivel milling spindle (±90°~±120°)

5.Automatic tool magazine (40–120+ tools)

Typical Application Industries

1.Aerospace: turbine disks, blisks, structural parts

2.Medical: hip joints, bone plates, surgical instruments

3.Automotive: crankshafts, camshafts, turbocharger impellers

4.Energy: valve bodies, pump housings

5.Precision molds and high-end general machinery

In short, turning-milling composite technology represents the highest level of modern metal cutting: “Done in One” — complete or near-complete machining of complex parts in a single machine and single setup, achieving maximum precision and efficiency. It is one of the core equipments in today’s smart factories and Industry 4.0 implementations.