Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- The difference between 3D printing and Vacuum molding

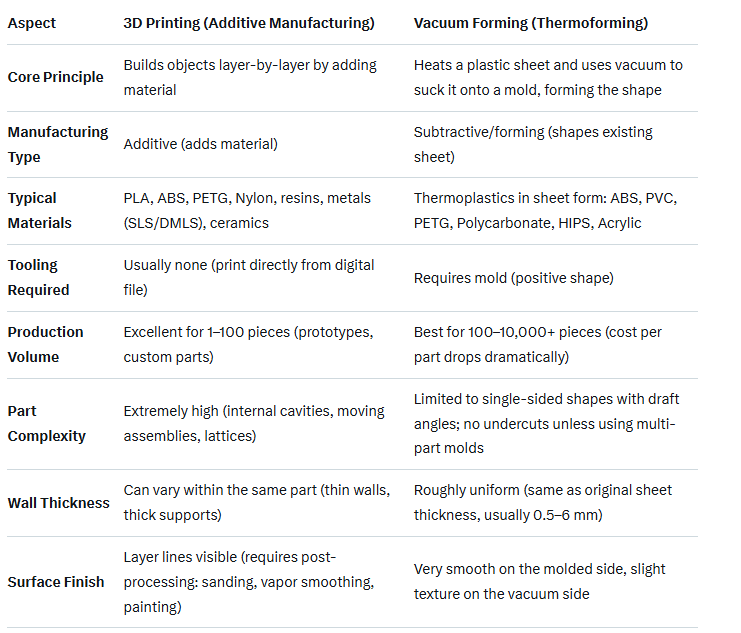

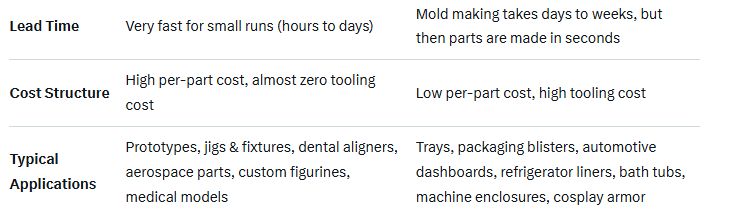

Overview of the Two Processes

Key Advantages & Disadvantages

3D Printing

Advantages: No tooling, unlimited geometric freedom, easy design changes, functional end-use parts possible (especially with engineering resins/metals).

Disadvantages: Slow for large volumes, expensive per part when scaled, visible layer lines, limited material selection compared to injection molding.

Vacuum Forming

Advantages: Extremely cheap at medium-high volumes, excellent surface finish, very large parts possible (car bodies, boat hulls), fast cycle times (10–60 seconds per part).

Disadvantages: Requires a mold for every new shape, limited to relatively thin-walled, single-surface parts, significant material waste (trimming the excess sheet), draft angles required.

In short: 3D printing is “digital” and tool-less, perfect for low-volume complexity; vacuum forming is a classic high-volume plastic forming process that still requires physical molds but is unbeatable on cost and speed once the mold exists.