Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Why use alloys instead of pure zinc in pressure die-casting?

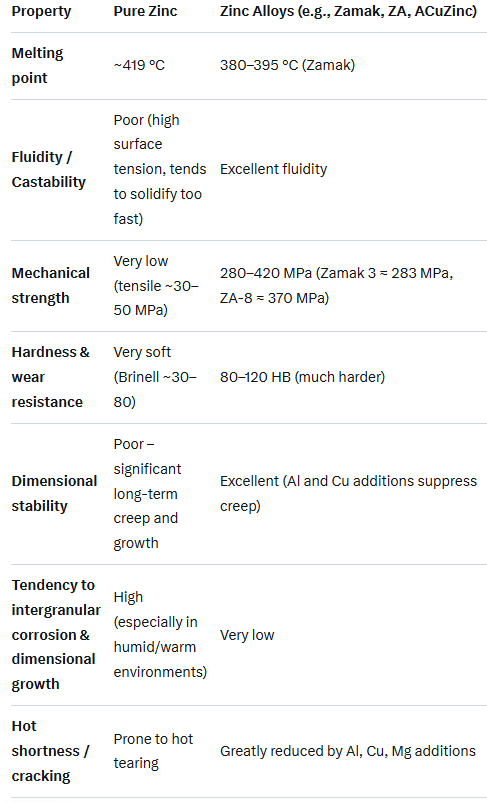

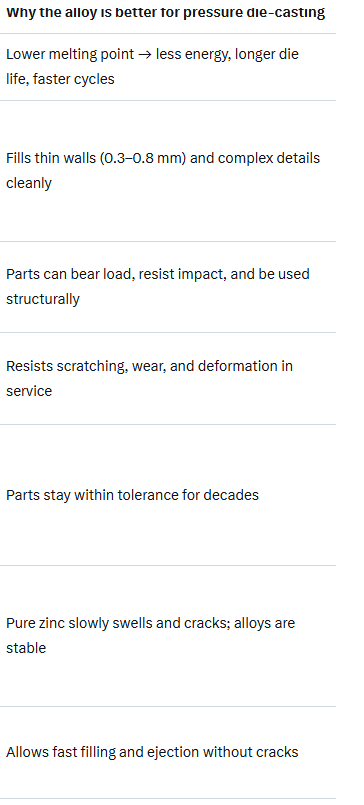

In pressure die-casting, pure zinc is almost never used; instead, specific zinc alloys (most commonly ZAMAK 3, ZAMAK 5, ZA-8, ZA-12, ZA-27, or ACuZinc) are the standard materials. Here are the main reasons why alloys are vastly preferred over pure zinc:

Key alloying elements and what they do

1.Aluminum (3–4% in Zamak, up to 27% in ZA alloys)

→ Improves fluidity, strength, suppresses intergranular corrosion, lowers melting point.

2.Copper (0.5–3% or up to 5% in ACuZinc)

→ Increases hardness, tensile strength, and creep resistance.

3.Magnesium (0.02–0.05%)

→ Prevents intergranular corrosion and die soldering, refines grain.

Summary

Pure zinc is soft, weak, dimensionally unstable, corrosive in many environments, attacks dies aggressively, and has poor fluidity for thin-wall high-pressure casting. Modern zinc die-casting alloys were developed precisely to eliminate all of these problems while retaining zinc’s advantages (low melting point, excellent platability, low cost, recyclability). That is why you essentially never see pure zinc used in pressure die-casting today — the alloys are vastly superior for virtually every commercial application.