Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- Why is zinc used to produce die casting?

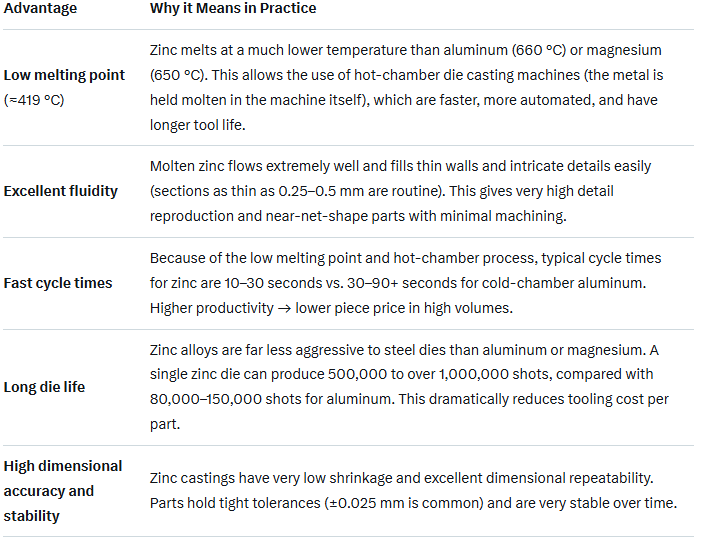

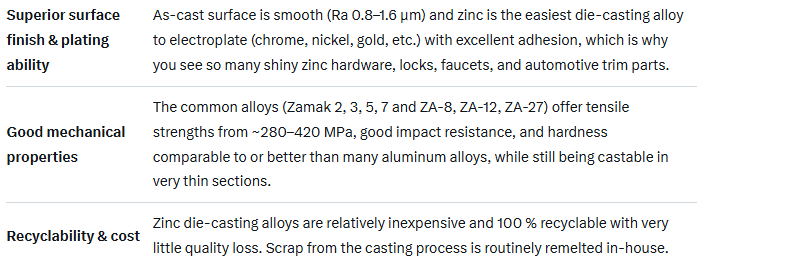

Zinc is one of the most popular materials for die casting (especially hot-chamber die casting) for several technical, economic, and performance reasons:

Most common zinc die-casting alloys

1.Zamak 3 (most widely used worldwide)

2.Zamak 5 (slightly stronger, common in Europe and North America)

3.ZA-8, ZA-12, ZA-27 (higher aluminum content → higher strength and creep resistance, usually cast in cold-chamber machines)

In summary, zinc dominates applications that need:

Very high production volumes

Thin walls and fine detail

Excellent plated appearance

Tight tolerances

Low total part cost

Typical parts:

Door handles, locks, carburetors, power-tool housings, zippers, builder’s hardware, automotive interior parts, electronic connectors, etc.Aluminum has largely replaced zinc in structural automotive parts (better strength-to-weight), but for small, precise, high-volume, beautifully finished components, zinc die casting remains unmatched.