Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- What is cnc prototype manufacturing?

What It Means

1.CNC = Computer Numerical Control machining (milling, turning, routing, etc.) where a computer controls the movement of cutting tools with extremely high precision.

2.Prototype = An early sample, model, or test version of a part used to evaluate form, fit, function, aesthetics, or manufacturability.

So CNC prototype manufacturing is using CNC machines to quickly and accurately produce one-off or low-volume parts directly from 3D CAD models, usually without the need for expensive hard tooling (like injection molds).

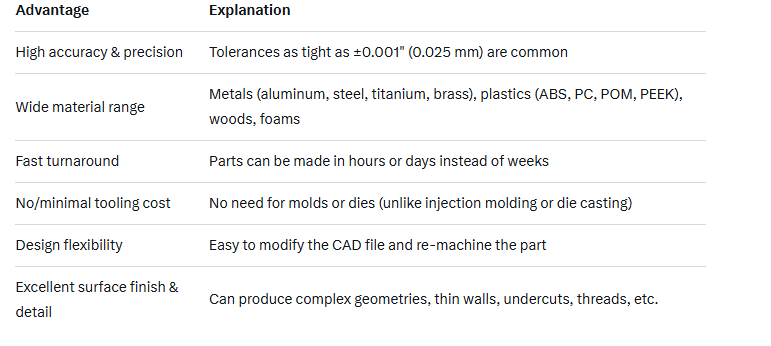

Why CNC is Popular for Prototyping

Typical Workflow for CNC Prototypes

1.Designer creates a 3D CAD model (SolidWorks, Fusion 360, etc.).

2.Engineer or machinist creates toolpaths using CAM software (Mastercam, Fusion 360, HSM, etc.).

3.Material block (blank) is fixtured on the CNC mill/lathe.

4.Machine cuts away material to produce the final part.

5.Post-processing: deburring, anodizing, polishing, plating, etc. (if needed).

Common Applications

1.Functional testing parts (brackets, gears, enclosures)

2.Fit-check and assembly mockups

3.Visual/aesthetic models

4.Medical device prototypes

5.Aerospace and automotive components

6.Consumer product development (before injection molding)

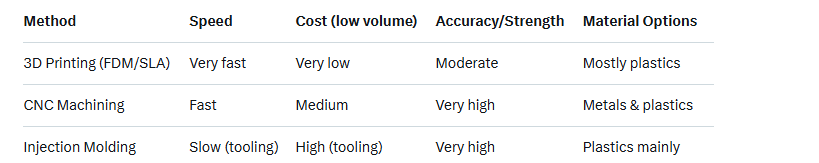

Comparison with Other Prototyping Methods

In short: CNC prototype manufacturing is the go-to method when you need real engineering materials, tight tolerances, and production-like quality in the prototyping phase, especially for parts that will eventually be mass-produced by CNC or other subtractive processes.