Shenzhen Alu Rapid Prototype Precision Co., Ltd.

Industry News

- Home

- News

- How to make PLA plastic injection mold ?

How to Make a Mold for PLA Plastic Injection Moldin

PLA (Polylactic Acid) is a biodegradable thermoplastic that can be injection molded, but it requires lower temperatures than most plastics (typically 180–220°C melt, mold temperature 20–60°C). The mold itself is almost always made from metal (aluminum or steel), not from PLA, because PLA would melt or deform under injection pressures and temperatures.

Below is a practical step-by-step guide to creating a real injection mold suitable for PLA (or any other plastic).

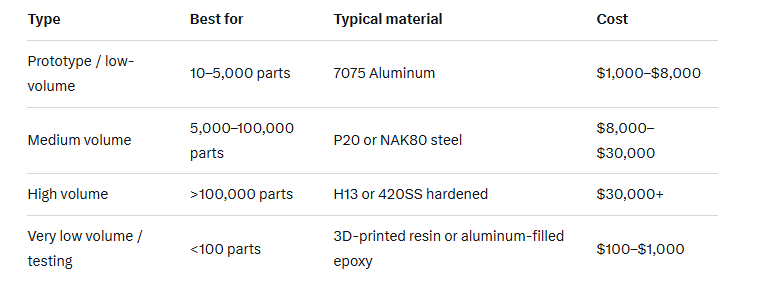

1. Choose the Mold Type and Complexity

For PLA you can perfectly use an aluminum mold — it dissipates heat fast, which helps PLA cool and crystallize nicely.

2. Design the Part for Injection Molding

A.Uniform wall thickness (1.5–3 mm ideal for PLA)

B.Draft angles 0.5–2° per side

C.Avoid undercuts or use side-actions/lifters

D.Add proper radii (minimum 0.5 mm) to avoid stress concentration

3. Create the Mold Design

A.Core and cavity inserts

B.Runner system (cold runner is fine for PLA)

C.Cooling channels (very important for PLA cycle time)

Ejector pins

D.Alignment pins, parting line, venting (0.02–0.05 mm vents)

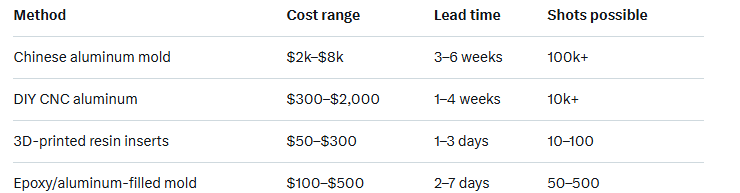

4. Manufacturing Routes

A. Professional Mold Maker (recommended for anything beyond prototype)

B. DIY / Low-Volume with CNC or 3D-Printed Master + Cast Aluminum

C. Desktop CNC Route (most practical DIY)

D. 3D-Printed Mold Inserts (only for very low pressure or wax/PLA testing)

5. Essential Mold Features for PLA

A.Mold temperature: 20–60°C (use water lines; higher temp → better clarity, lower temp → faster cycle time)

B.Generous venting (PLA releases gases)

C.Polished surfaces (PLA sticks more than PP or ABS)

D.Slightly larger gate (PLA is more viscous when not fully dried)

6. Drying PLA Before Injection

PLA must be bone-dry (<0.02% moisture) or you get bubbles, splay, and hydrolysis.

Dry 4–6 h at 60–70°C in a desiccant dryer.

Quick Cost & Time Summary